The new i-Series compact color MFPs house a powerful engine, a quad-core Central Processing Unit with standard 5 GB of memory and 256 GB SSD, which allows for quick-response and high-performance operations.

Meet tight deadlines with greater productivity

High-speed printing for short runs and quick turnarounds

125 ppm (A4 horizontal), 70 ppm (A3).

Significantly faster RIP speed with new CPU and optimised data processing.

Tandem output*: Max. 250 ppm (A4 horizontal).

*Optional

High paper capacity and on-the-fly consumable replacements

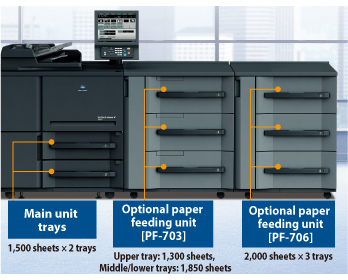

Max. paper capacity: 14,000 sheets with the large capacity paper feeding units*. Auto-tray switch function keeps operations going without missing a beat.

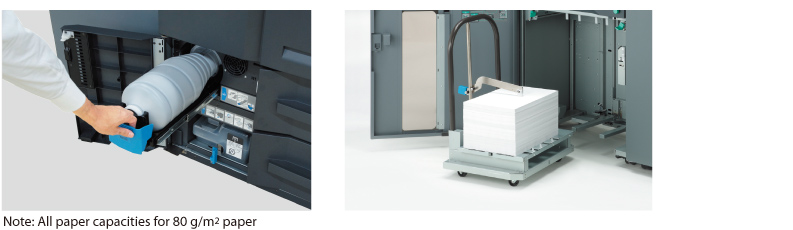

High-capacity toner can be replaced on the fly.

Large-capacity stacker* with cart holds up to 10,000 sheets (with 2 stackers in tandem).

*Optional

Create more business with greater paper handling

Greater thin and thick paper support

40 g/m2 thin to 350 g/m2 thick paper stock*

Thick paper support available only for optional Paper Feed Unit PF-703 and Paper Feed Unit PF-706 middle trays.

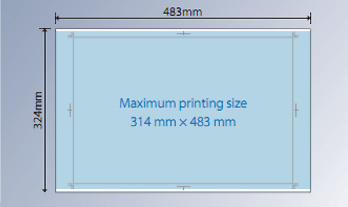

Full A3 outputs including crop marks

Max. 324 × 483 mm paper (314 × 483 mm printable area)*

* PF-703 required

Envelope printing

New envelope fuser unit option*

Paper other than envelopes cannot be fed when using the envelope fuser unit.Note: Please consult your service engineer for details regarding recommended paper,and envelope types and sizes.

Oher functions

Register up to 256 types of paper with the Paper List (proile)

Coated paper & embossed paper support

Error-free operation from start to finish

Air suction paper feeding system

The high capacity Paper Feeding Unit PF-703* adopts an air suction paper feeding system that better adheres the paper to the conveyance belt for stable conveyance at all times.

* Optional

Multi-feed detection sensor

An ultrasonic sensor detects multi-feeding to prevent blank pages from being mixed in with the output.

Paper skew sensor

This sensor detects paper skews to prevent misaligned printing

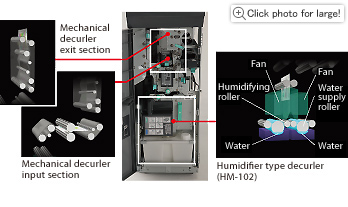

Hybrid decurling system*

The Relay unit RU-509* employs a mechanical decurler and a humidifier-type decurler HM-102* to prevent paper curls. Each system is used according to the paper type to maintain high quality outputs even for booklets.

Optional

Versatility to meet more orders

Versatility to meet more orders

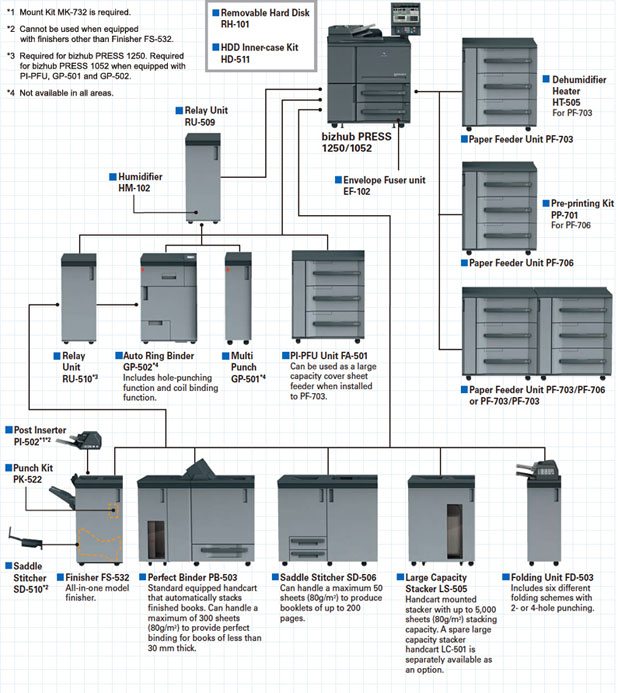

From hole punching, folding, corner and centre stapling to perfect binding, high-performance, high-productivity inline finishers allow the bizhub PRESS 1250/1052 to be optimally expanded to handle an abundance of orders.

Impressive image quality like never before

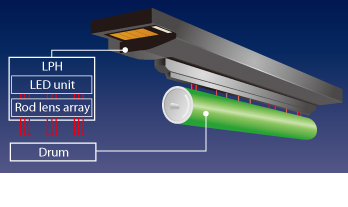

LED Print Head for 1,200 dpi high resolution outputs

Achieve true 1,200dpi resolution outputs with the LED Print Head (LPH) which offers clearer reproduction of small text and smoother halftones.

Screen settings

Pre-setting screens (2 types of resolution in 3 patterns each) and dot screens are provided to maintain high resolution. High quality print images are provided by using the optimal screen to match the output.

| Preset screen | 1,200dpi | 600dpi | |

| Photo mode | Smooth gradations even for low-resolution photos | 120lpi | 86lpi |

| Text/Photo mode | Optimal setting for both text and photos | 170lpi | 106lpi |

| Text mode | Even small text are clearly printed for easy legibility | 212lpi | 141lpi |

Front and back printing position adjustments

Highly accurate front- and back-side registrations are possible with image shift and independent magnification adjustment. Even the slightest shifts can be minutely adjusted to achieve higher quality duplex printing, trimming and bookbinding.

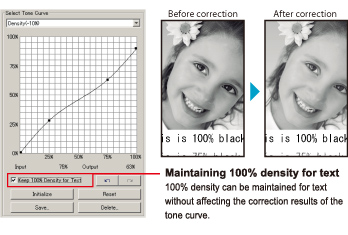

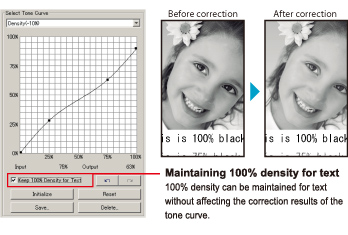

Tone curve utility

Fine tune brightness and contrast before printing without a dedicated software. Tone curve utility corrects these without affecting the density of text for true professional results.

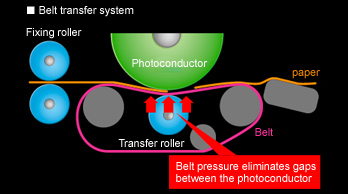

Belt transfer system

The belt transfer system improves the quality of the transferred images and paper feeding. The paper is adhered onto the transfer belt to eliminate any gaps, ensuring that the toner is consistently fixed onto the belt without unevenness. Incidences of images being cut at the paper’s edge and transfer shifts caused by nip resistance are also minimised.

CIE colour space

When outputting a colour original, the inputted image is temporarily converted to a CIE colour space and then optimally processed by converting it in the main unit’s colour space. This method faithfully reproduces shadowed areas of images over the conventional simple conversion formula to provide richer gradation expressions.

*Output speed will be 10-20% slower.

Simitri HD toner

Simitri HD toner’s optimised toner particle structure and smoother fixing improve transfer performance for clearer reproductions of small text and thin lines, as well as providing richer halftones and gradations for photos. Its low temperature fixing reduces paper curls and waviness to eliminate paper shifts during stapling and folding.

Improve efficiency with advanced operations

Improve workflow efficiency with job management

Streamline complex output operations with flexible workflow management.

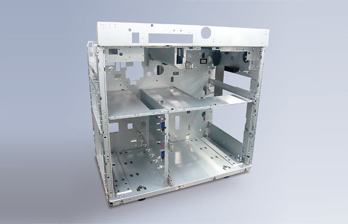

Highly rigid frame and highly durable parts

The bizhub PRESS 1250/1052 is built to withstand heavy and continuous use. The highly rigid frame with box-shaped dual-structured chassis prevents the main unit from vibrating and twisting for longer lasting performance.

High affinity with bizhub office devices

Main unit authentication and IC card authentication

Reinforce information security with the main unit authentication which supports external servers such as Active Directory and centralised management of user information; and touch-type authentication using non-contact IC cards which only allows bizhub access with employee IDs.

* Optional

Use of recycled materials

Konica Minolta prioritises the use of materials and parts with low environmental impact for the bizhubs. Environmentally considerate recycled PC/PET and plant-based bioplastic are employed throughout the bizhub PRESS 1250/1052.

Centralised management and TCO reduction

Numerous technologies to reduce waste, energy and unnecessary costs are employed throughout the bizhub PRO 951 without sacrificing quality and productivity. And centrally manage all of your output devices with PageScope Enterprise Suite for smoother operation.

| bizhub PRESS 1250/1250P | bizhub PRESS 1052 | ||

| Type | Console Full Colour Printer/Copier/Scanner | ||

|---|---|---|---|

| Resolution | Scan | 600 × 600 dpi | |

| 1,200 × 1,200 dpi | |||

| Gradation | 256 | ||

| Original Type | Sheets, Books, Objects | ||

| Max. Original Size | A3 (11″ × 17″) | ||

| Memory Capacity | DIMM | 768 MB | |

| HDD | 250 GB | ||

| Output Size

(S: Short edge feed |

SRA3, A3 to B5, A5S, Tab paper, Custom 95 × 133 mm (Using small size guides) to 324 × 463 mm | ||

| Image Loss | Max. 3 mm or less for top edge, Max. 2.0 mm or less for bottom edge, Max. 2.0 mm or less for right/left edges | ||

| Warm-Up Time | 480 sec. or less | ||

| First Copy Out Time | 2.8 sec. or less | 3.0 sec. or less | |

| Copy / Print Speed (A4) | 125 ppm | 105 ppm | |

| Copy Magnification | Fixed Same Magnification | 1:1±0.5% or less | |

| Scaling Up | 1:1.154/1.224/1.414/2.000 | ||

| Scaling Down | 1:0.866/0.816/0.707/0.500 | ||

| Preset | 3 types | ||

| Zoom | 25 to 400% (in 0.1% increments) | ||

| Paper Capacity(80g/m2) | Standard: 1,500 sheets × 2 | ||

| Paper Weight | Standard | 40 to 300 g/m2 (Limitations to paper types apply) | |

| Option | 40 to 350 g/m2 (Only available for middle tray of PF-703 and PF-706) | ||

| Multiple Copy | 1 to 9,999 sheets | ||

| Auto Duplex

(S: Short edge feed |

Non-Stack SRA3, A3 to B5, A5S | ||

| Power Requirements | 220 to 240 V/25 A | ||

| Max. Power Consumption (Main unit + PF-706 + FS-532) | 5.0 kW or less | ||

| Dimensions [W] × [D] × [H] | 990 × 910 × 1,234 mm (39″ × 35-3/4″ × 48-1/2″) (Main unit + ADF) 1,211 × 910 × 1,454 mm (47-3/4″ × 35-3/4″ × 57-1/4″) (including operation panel) | ||

| Weight | 364 kg (802-1/2 lb) (Main unit) | ||

| Space Requirements [W] × [D] | 3,420 × 980 mm (134-3/4″ × 38-1/2″) <Main unit + RU + FS +PFU> | 2,930 × 980 mm (115-1/2″ × 38-1/2″) <Main unit + RU + FS +PFU> | |

| bizhub PRESS 1250 | bizhub PRESS 1052 | ||

| Type | Embedded | ||

|---|---|---|---|

| CPU | Pentium G6950 2.8 GHz | ||

| Memory | 2 GB | ||

| HDD | 250 GB 3.5 inch SATA | ||

| Print Speed | 125 ppm | 105 ppm | |

| Print Resolution | 1,200 × 1,200dpi, 600 × 600dpi | ||

| PDL | PCL5e/6, PostScript3 (3019), PDF Ver1.7, TIFF Ver. 6 Emulation, PPML (Ver2.2) | ||

| Protocol | TCP/IP, IPX/SPX (NDS support), SMB (NetBEUI), IPP, EtherTalk | ||

| Support OS | PCL | Windows XP Home Edition/Professional, XP Home Edition/Professional 64bit, Server 2003 Standard/Enterprise, Server 2003 Standard/ Enterprise 64bit, Vista/Vista 64bit, Server 2008/Server 2008 64bit, 7/7 64bit | |

| PS/PS-Plug-in | Windows XP Home Edition/Professional, XP Home Edition/Professional 64bit, Server 2003 Standard/Enterprise, Server 2003 Standard/Enterprise 64bit, Vista/Vista 64bit, Server 2008/Server 2008 64bit, 7/7 64bit Mac OS X 10.3 (PS PPD only), 10.4 (PPC/Intel), 10.5 (PPC/Intel), 10.6 (Intel) | ||

| Fonts | PCL | 80 fonts | |

| PS | 136 fonts | ||

| Interface | 10Base-T/100Base-TX/1000Base-T, USB2.0 (Hi-Speed) | ||

| Type | Monochrome | |

|---|---|---|

| Scanning Speed (A4) | 96 opm | |

| Scanning Size | Conforms to main unit specifications | |

| Scanning Resolution | 1200×1200 dpi equiv., 600×600 dpi, 400×400 dpi, 300×300 dpi, 200×200 dpi | |

| Protocol | TCP/IP (FTP, SMB, SMTP, WSD) | |

| Support OS | Windows XP/XP 64bit/Vista/Vista 64bit/7/7 64bit | |

| Interface | Ethernet 10Base-T/100Base-TX/1000Base-T | |

| Output Format | PDF, TIFF, Linearised PDF, XPS | |

| Type | Reverse Automatic Document Feeder | |

|---|---|---|

| Original Size (S: Short edge feed |

A3 to B6S, Custom (128 × 139.7 to 297 × 431.8 mm) | |

| Paper Weight | Simplex | 50 to 210 g/m2 |

| Duplex | 50 to 130 g/m2 | |

| Paper Capacity (80 g/m2) | Max. 100 sheets | |

| Dimensions [W] × [D] × [H] | 650 × 570 × 170 mm (25-1/2″ × 22-1/2″ × 6-3/4″) | |

| Weight | Approx. 22 kg (48-1/2 lb) | |