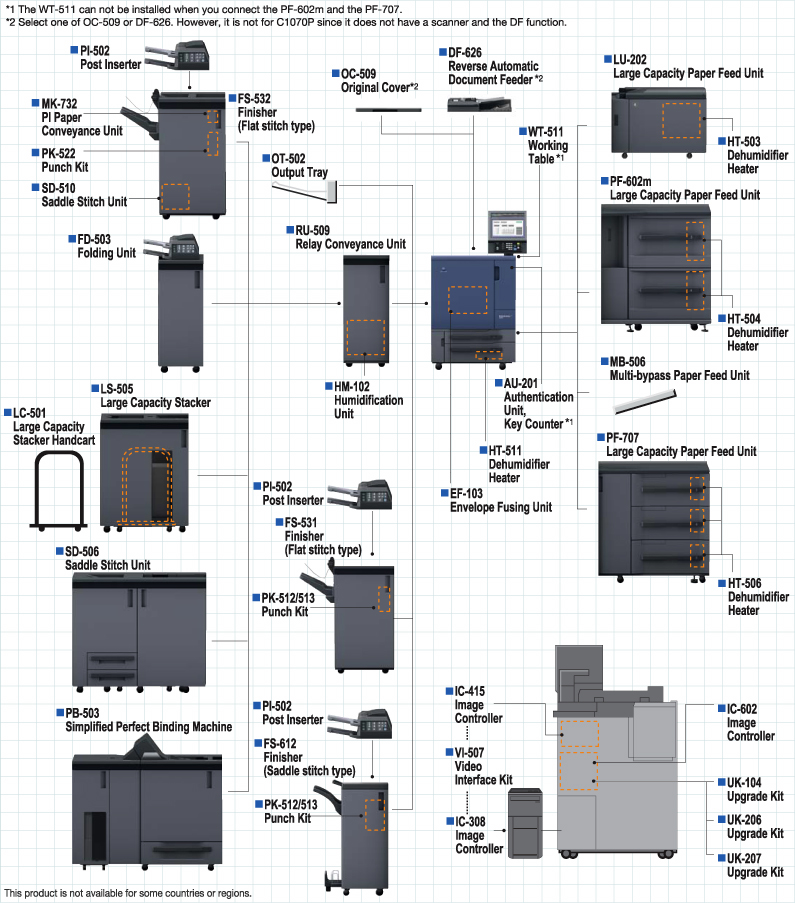

The bizhub PRESS C1070/C1060P Digital Printing Press for digital color printing adds power, performance and simplicity to any production print application -- up to 70 ppm print/copy output, familiar PC-like operation with hand-held mouse, real-time image density and color density control sensors, and digital color imaging to rival offset printers at a fraction of the cost.

Key features

Durable Performance

10.1" Colour touch panel

High Productivity

10.1" Colour touch panel

Readymade Print Products

Print from advanced mobile & cloud technology

Perfect Image Quality

Low environmental impact

Higher accuracy, higher stability - Deliver stable quality results that meet expections

Achieve offset-like results that meet expectations. Gain the competitive edge with high-qualityand high-accuracy finishes which exceed competitive light-production printers.

The Thorough Pursuit For Offset Quality

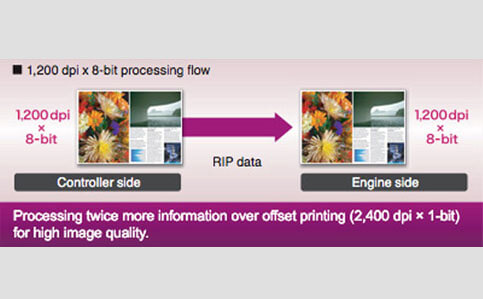

High Resolution Technology For Beautiful Reproductions 1,200 dpi x 8-bit high quality & precision

Reproduce minute text and thin lines clearly as well as rich colour gradations even for colour images through synergy with 1,200 × 1,200 dpi high-resolution printing and Simitri HDE toner.

256-step 8-bit processing controller and engine

Eight-bit multi-gradation data processing flow for each colour displays 256-step gradations within a single pixel. Both colour and monochrome data can be processed in 1200 dpi x 8-bit resolution.

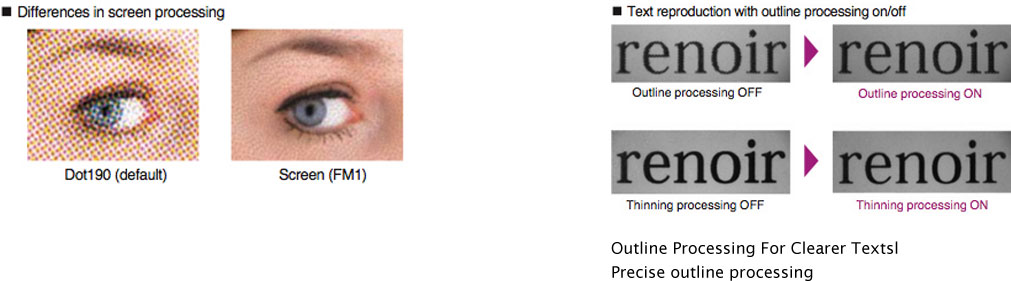

Optimise Print Quality According To The Output Material

New FM screen processing

FM (Frequency Modulation) screen processing fully leverages the C1070 series’ 1,200 dpi resolution. Improved 1,200 dpi FM screens with enhanced resolution and granularity eliminate jaggedness and moiré for smoother reproductions. In addition, the optimal screen processing can also be selected to match the quality required for the output based on the dots and lines.

High precision outline processing practically eliminates blurs and raggedness of lines, normally associated with digital printing, to reproduce text details in higher definition. Quality is even improved for outputs that combine coloured text with thin lines and sharp outlines.

High Stability Take Duplex Printing, Folding, And Trimming To The Next Level

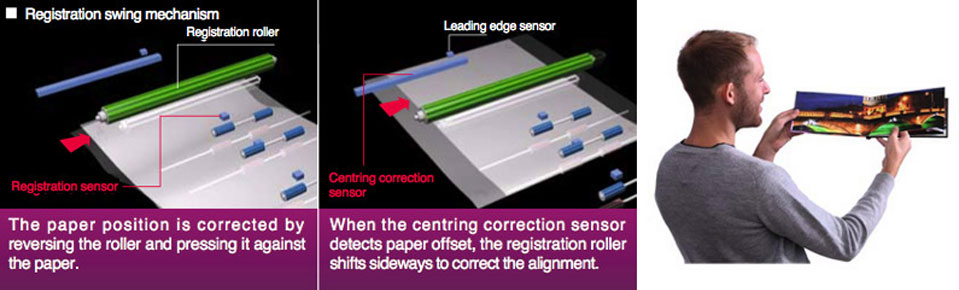

Enhance Print Position Accuracy

Higher print position accuracy

The newly developed registration swing mechanism is standard-equipped with a centring detection sensor on the registration portion of the engine to provide high-precision centring correction.High resolution technology for beautiful reproductions.

Consistent And Stable Outputs From The First Print To The Last

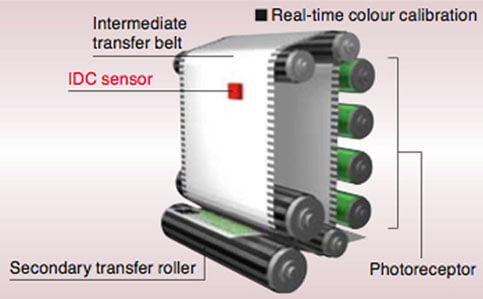

Further Improved Colour Reproduction Stability Real-time colour calibration

This function controls image stability in short intervals during continuous printing by detecting density correction patches on the intermediate transfer belt and dot diameter correction patches with the IDC sensor, providing stable high quality outputs for a wide range of densities. range of densities. (Operates only when the Stabilization Adj Operation Setting is set at “Stability”.

High Stability Take Duplex Printing, Folding, And Trimming To The Next Level

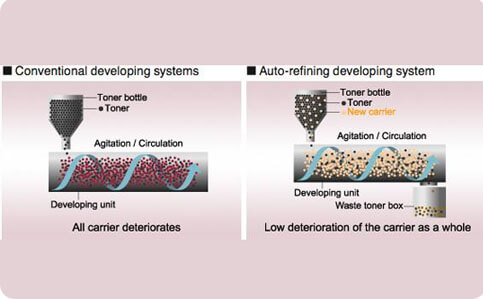

Adopted for all four colours, auto-refining developing delivers stabilised high quality even for full colour images. New carrier along with the toner is regularly supplied to refresh the developer, stabilising the developer condition to maintain high quality outputs over the long term. Its longer life also helps to minimise downtime.

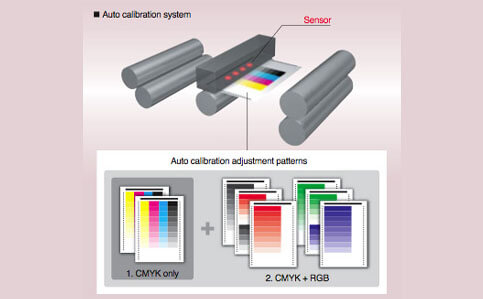

Further Improved Colour Reproduction Stability Konika Minota's proven auto calibration system

Enhanced colour density adjustment function with Relay Unit RU-509

Correct the gradation density to match the characteristics of the output paper. Auto calibration offers up to 15 correction values according to paper or screen type. In addition, a mode that measures RGB as well as CMYK for the target colour further enhances accuracy.

* Optional. Equipped in RU-509

Expanded Range of orders Greatly expand the range ofdigital printing orders.

Expand the range of printing orders to unprecedented levels with the industry’s top-class range of media handling. Create more business opportunities for print providers by handling a wide range of applications essential for digital printing.

Flexibility To Deliver With Speed

Quick Turnaround

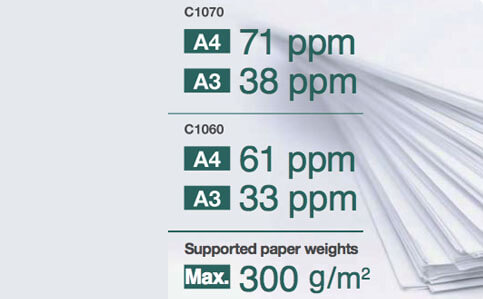

High Productivity At 71 Pages Per Minute

At 71 ppm* for the C1070 and 61 ppm* for the C1060 in both colour and monochrome, the C1070 series boosts productivity to meet large orders with ease. And with 38 ppm*2 productivity for A3 size outputs, booklets and imposition data can also be processed right away.

*1 A4 crosswise using 62 to 176 g/m2 paper.

*2 Using 62 to 176 g/m2 paper for C1070.

Enhanced Thick Paper Productivity

Equal Speed Productivity For 62 To 176 G/M2 Paper

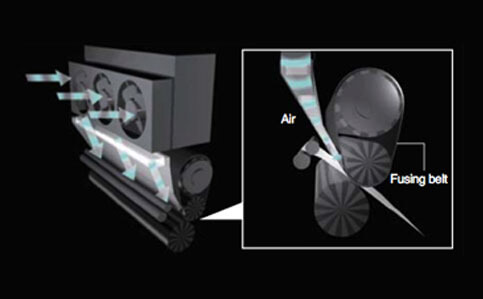

Productivity is now even more efficient, whether using normal paper or coated, and for simplex or duplex printing, thanks to the improved fusing unit and process control. The C1070 series maintains high-speed outputs of 71 ppm* for paper up to 176 g/m2, boosting productivity even for mixed media.300 g/m2 boosting productivity even for mixed media.

A4 crosswise for C1070. 61 ppm for C1060.

High Capacity Plus High Efficiency Paper Feeding Maximise Uptime

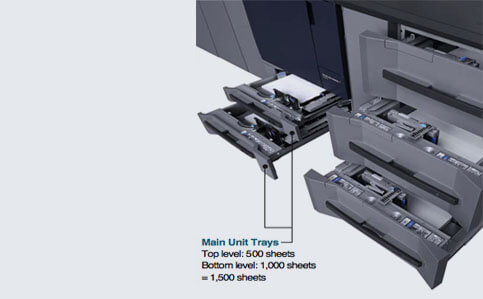

Max. 7,500-Sheet Paper Feeding Capacity

In addition to the 1,500-sheet capacity main unit trays, three types of paper feeding units are available for a maximum capacity of 7,500 sheets. Paper can be replenished on the fly to minimise downtime and maximise productivity regardless of the printing volume. A Multi-bypass Unit (MB-506) is also available for manual paper feeding.

From Thin To Thick, Coated And More –Media Handling That Empowers Your Business

Stabilised Paper Conveyance

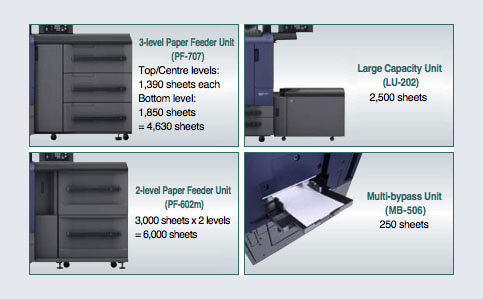

Air Suction Belt Paper Feed System (PF-707)*

The newly developed Suction Feeder PF-707, which was previously only supported for mid-production models, is now available for the bizhub PRESS C1070 series. The air assist function blows air from the sides and front to raise each sheet of paper to stick on the suction belt for conveyance, realising stable and damage-free paper feeding, even for thick and coated sheets.* Optional

Reliable Thin Paper Conveyance

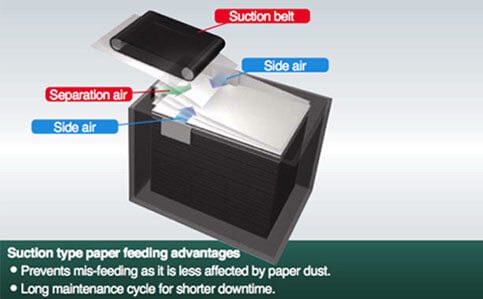

Air Blow Fusing Separation Mechanism

Air is blown to the area around the fusing nip to prevent the paper from winding around the roller. This also increases conveyance performance, greatly enhancing separation performance for thin sheets of paper. Air volume can be set automatically or manually according to paper type.

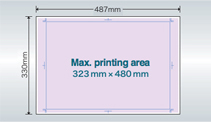

Cover The Entire Page A3 Full-Bleed Printing

The main unit’s Tray 2 and all optional trays can accommodate custom sized paper up to 330 x 487 mm for a maximum printing area of 323 × 480 mm, allowing full-bleed A3-size printing with registration marks, as well as A4 size imposition printing with registration marks.

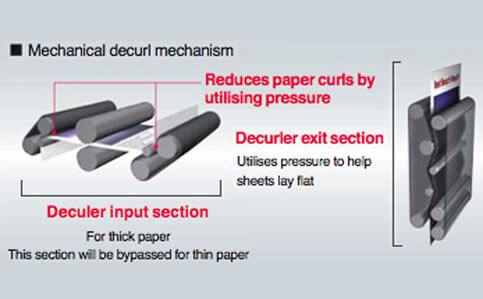

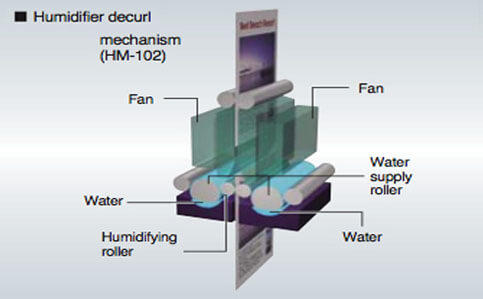

Eliminate Paper Curls And Static

Hybrid Decurler*

Create a hybrid curl correction system to prevent paper curls by combining the Relay Unit (RU-509), which employs a mechanical decurler, with the optional Humidifier Kit (HM-102). Paper curls can be optimally removed according to paper type, such as the mechanical decurler for coated sheets and the humidifying curler for non-coated sheets. The decurl amount can be adjusted manually, and responds flexibly to the changes in conditions.

Mechanical decurler

Standard equipped Relay Unit (RU-509) employs a zigzag paper passage that reduces paper curls. Decurling strength can be adjusted in five steps for the optimal curl removal for thin paper to cardstock.

Humidifier type decurler*

In addition to removing curls using humidification for uncoated paper, HM-102 controls paper absorption by removing heat and minimising static electricity.

Create New Business With Postcard Printing

Postcard Printing*

Install the required options for high-volume postcard-size printing including direct mailings and invitations. Use with variable printing to create new business opportunities.

* With optional Paper Feeder Unit (PF-707/PF-602m) or Multi-bypass Unit (MB-506) installed.

For High-On-Demand Envelope Printing

Envelope Printing*

Expand your business opportunities by taking on new orders. The Envelope Fuser Unit (EF-103) supports printing for 100 × 148 mm to 248 × 375 mm envelopes. The optimally designed fusing roller almost eliminates wrinkles and ruffling, and the suction type paper feeder unit ensures pickup and conveyance from start to finish.

* Supported with optional Paper Feeder Unit (PF-707).

* Envelope Fusing Unit must be installed by the customer. Please contact your local Konica Minolta service provider for information regarding applicable envelope types.

Meeting the global standard Standard Conduct business with confidence by meeting global standards.

Supports various printing industry standards and position colour management. This latest global standard model satisfies printing industry standards.

Proven Colour Management With High Affinity With The Engine

Konica Minolta Image Controller (IC-602) * Optional

Professional Image Quality IC-602 employs Konica Minolta’s proprietary colour management developed especially for commercial printing.

APPE 2*

Adobe’s original APPE 2.6 (Adobe PDF Print Engine 2.6) directly processes PDF files without having to access a printer driver for a proper transparent effect.

Control Panel Job Management And Editing

Manage jobs, edit job tickets and pages with outstandingly intuitive and efficient operations.

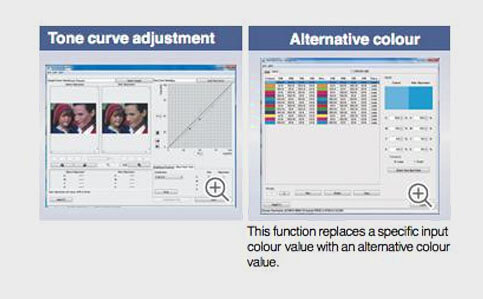

Furthermore, tone curves can be adjusted using the same operations as Color Centro.Command WorkStation 5 (IC-308) (IC-415) Additional apps for printing operations

Job Centro (Job Management Utility)

Manage jobs from the PC’s interface. The screen includes indicators and thumbnails to make operation more efficient.

Color Centro (Colour Management Utility)

Create colour profiles and set and edit various colours with this ingenious colour management software.

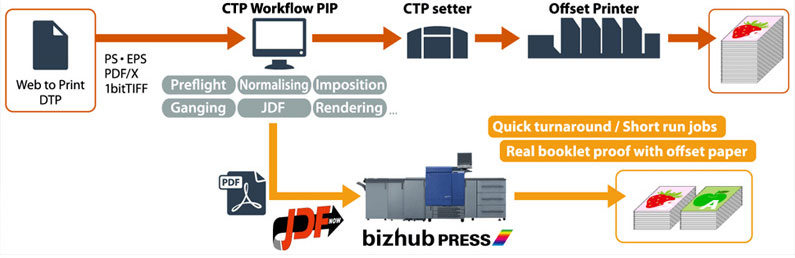

CTP Workflow RIP Connectivity

CTP workflow connectivity with bizhub PRESS is realised via JDF.

Multi-Functional Controller With Proven Interface, Imposition And More

Fiery Image Controller (IC-308)* Optional

Fiery Image Controller (IC-415)* Optional

High-Speed Processing & High Image Quality

Achieve high-speed processing with 1,200 dpi x 8-bit ripping and a 71 ppm (A4 crosswise) print engine. In addition, a wide choice of colour profiles lets you manage colours the way you want.

Variable Printing (IC-308) (IC-415)

Variable printing, including Fiery FreeForm, PPML* are supported, making impositions easier for more efficient processing.

* PPML only available for IC-308

APPE 2 (IC-308)

The new rendering engine APPE 2.5 (Adobe PDF Print Engine 2.5) offers transparent effect processing of PDF files as standard.

Command WorkStation 5 (IC-308) (IC-415)

Mange jobs effectively with both the Job Centre and Device Centre screens from your PC.

Job Centre

Integrating all job management functions

1) Direct drag & drop operations

2) Grasp job and server information on the same screen

3) Customisable tool bar to match usage functions

4) Full-screen jobpreview before and after RIP processing

Device Centre

Aggregating server setting functions in a single screen

1) Universal profile simulation settings using intuitive colour setting tools

2) Paper catalogue for tray settings from either the device or controller

3) Efficient job log management function

Colour Management (IC-308) (IC-415)

Performs colour management for CMYK, RGB, spot colours and more, regardless of the application or file format for conducting colour management according to purpose, such as for proofing or the production of the final product.

Additional Apps For Printing Operations* Optional

SeeQuence Impose (IC-308) (IC-415)

Create impositions of print jobs for variable data, in addition to business cards and saddle-stitched booklets. Also available for Mac OS.

Graphic Arts Package, Premium Edition (IC-308)

Includes data checking functions such as Image Viewer, Preflight and Postflight, a colour correction function, halftone screen function for changing halftone angles, shapes, the number of lines, and more.

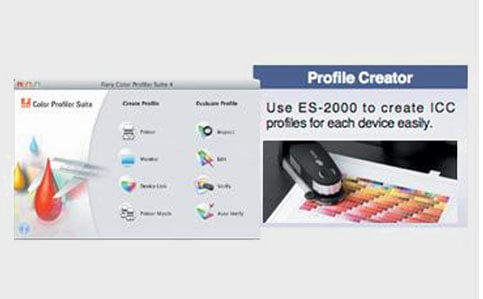

EFI Color Profiler Suite (IC-308) (IC-415)

Create, edit and manage the quality of the ICC profile required for colour management

Reduced Environmental Impact Contributing to A Sustainable Society Because it's a production machine

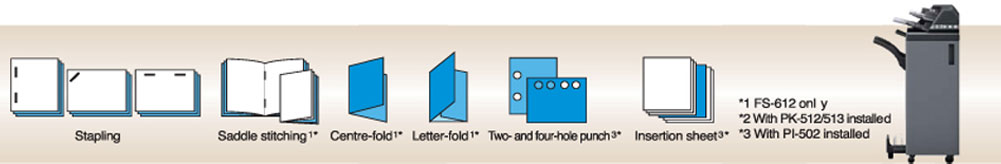

All-In-One Finisher (FS-532) * Optional

FS-532 stapling finisher with staple cutter provides stapling for up to 100 sheets*1 for beautiful finishes regardless of the number of sheets through enhanced paper output consistency and a refined paper path. And a choice of three sub-options can be fitted to expand the system when required.

*1 Stapling for up to 50 sheets for A3 paper.

* Compared to previous C7000.

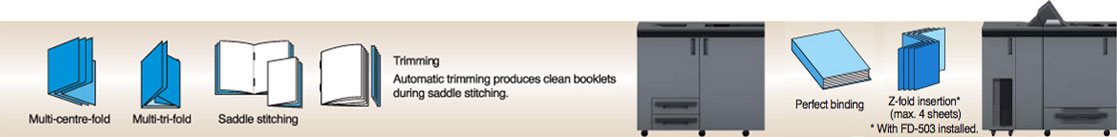

Saddle Stitcher (SD-506) * Optional

Effective for manuals and catalogues in small lots, SD-506 creates booklets of up to 50 sheets (200 pages). And the saddle-stitching system increases folding strength and accuracy, reducing paper offset during binding. In addition to multi-centre-fold and multi-tri-fold, a trimming function for creating clean-cut booklets is standard equipped to streamline post-processing tasks including bookbinding.

Perfectly binds up to 300 sheets (600 pages) or up to 30 mm thick. Cardstock up to 216 g/m2* can be used for the cover, and inline printing and gluing is also available. Advanced paper alignment realises clean binding that eliminates three-way trimming, along with high productivity. In addition, books are automatically loaded onto the cart when finished.

* Max. 91 g/m2 for the inner pages when using a cover.

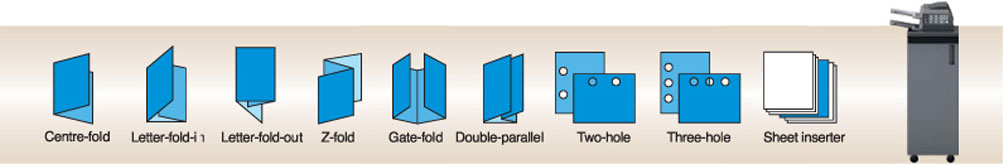

Multi-Folding Unit (FD-503) * Optional

EFD-503 provides a variety of folding functions, including centre-fold, letter-fold-in, letter-fold-out, double-parallel, Z-fold and gate-fold for creating materials such as direct mailings, as well as two or three-hole punching. A paper inserter for setting two types of paper is also equipped.

Stapling Finishers (FS-531/FS-612) * Optional

Ideal for producing marketing collateral and corporate documents, these compact units staple up to 50 sheets* of paper and can be expanded with the optional PK-512/513 Punch Kit and/or PI-502 Post Inserter. FS-612 also offers centre and letter folding capabilities and saddle stitches up to 20 sheets* for producing 80-page booklets.

Note: The number of punch holes may vary depending on the market. * 80 g/m2 paper

The LS-505 is designed to streamline operations with a capacity for 5,000 sheets and includes a cart. Up to two units can be installed side-by-side for a total capacity of 10,000 sheets, and finished documents can be taken out with the cart for easy transport to the next step. A sample ejection function allows quality checking to be made during large volume printing.

Usability Mouse-Supported Control Panel

Easy to see and operate, the 15-inch large screen display allows the display angle to be adjusted to match the user, and ensures outstanding operability with the user-friendly GUI and guide messages, even for various settings. A USB mouse can also be connected to ease operability.

Compact, Lightweight With Fewer Parts

The bizhub C1070/C1060 are 17.5 percent* lighter and use fewer parts, yet still remain highly robust. CO2 emissions have been reduced during production and transportation, and they help reduce environmental impact and conserve resources throughout their lifecycles.

* Compared to previous C7000.

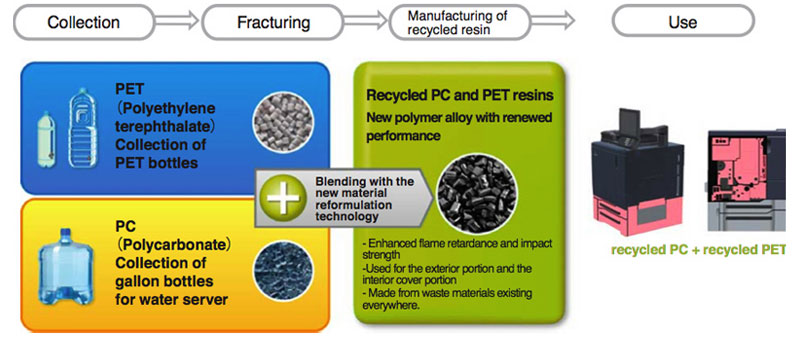

Environmentally Considerate Materials

The C1070 series uses a high combination of recycled resins and bioplastics. Resources are effectively used and environmentally considerate materials are actively employed. A lead-free shaft is also adopted to protect the environment as well as the user’s health.

Energy-Saving Design

In addition to the energy-saving performance targeted by Simitri HDE toner, an optimised transfer process reduces fusing temperatures by about 20 degrees to reduce energy use.

Meeting Ecological And Environmental Demands

KONICA MINOLTA products are designed with the environment in mind.

☻ Energy Star Certified ☻ RoHS Compliance ☻ WEEE Compliance

☻ Eco-friendly Toners ☻ Production at ISO Certified Factories

Environmentally Considerate Resource Utlisation

Plant-based bioplastic and recycled polycarbonate/PET are proactively used for the main unit to reduce impact on the environment.

| bizhub PRESS C1070 | bizhub PRESS C1060 | ||

| Type | Console type | ||

|---|---|---|---|

| Copy Method | 4-coupled drum tandem laser electrostatic method | ||

| Resolution | Scan | 600 dpi × 600 dpi | |

| 1,200 dpi (Equivalent to 3,600 dpi) × 1,200 dpi | |||

| Gradation | 8-bit / 256 Gradation | ||

| CPU | Core i5 2400 3.1 GHz | Pentium G850 2.9 GHz | |

| System Memory Capacity | 6 GB | ||

| HDD | 1.5 TB | ||

| Original Type | Sheet, Book, Solid object | ||

| Max. Original Size | A3 or 11×17 | ||

| Max. Printing Area | 323 mm × 480 mm | ||

| Output Size (S: Short Edge Feed |

SRA3, A3, B4, A4, B5, 13 × 19, 11 × 17, 8 1/2 × 14, 8 1/2 × 11,5 1/2 × 8 1/2S Tab paper (A4, 8 1/2 × 11) Max. 330 mm×487 mm, Min. 140 mm × 182 mm Multi-bypass(Option): SRA3, A3, B4, A4, B5, 13 × 19, 11 × 17, 8 1/2 × 14, 8 1/2 × 11, 5 1/2 × 8 1/2S Tab paper (A4, 8 1/2 × 11) Max. 330 mm × 487 mm, Min. 100 mm × 148 mm |

||

| Image Loss | Max. 4 mm or less for top edge, Max. 4.5 mm or less for bottom edge, Max. 3.0 mm or less for right/left edges |

||

| Warm-Up Time | 390 seconds or less | ||

| First Copy Out Time | Colour | 7.1 seconds or less (A4, 8 1/2 × 11) | 7.6 seconds or less (A4, 8 1/2 × 11) |

| Black and White | 5.9 seconds or less (A4, 8 1/2 × 11) | 6.3 seconds or less (A4, 8 1/2 × 11) | |

| Continuous Copy Speed | Colour | 71 sheets/min. (A4) 38 sheets/min. (A3) |

61 sheets/min. (A4) 33 sheets/min. (A3) |

| Black and White | 71 sheets/min. (A4) | 61 sheets/min. (A4) | |

| Copy Magnification | Fixed Magnification | Inch : × 1.000, × 2.000, × 1.545, × 1.294, × 1.214, × 0.785, × 0.772, ×0.647, × 0.500 Metric : × 1.000, × 2.000, × 1.414, × 1.189, × 0.840, × 0.707, × 0.500 |

|

| Zoom Magnification | × 0.250 to × 4.000 (Each 0.001 step) | ||

| Tray Capacity | Standard | Tray 1 (500 sheets, 80 g/m2) Tray 2 (1,000 sheets, 80 g/m2) |

|

| Option | MB-506 (Multi-bypass, 250 sheets, 80 g/m2)*1*2 PF-602m (3,000 sheets × 2, 80 g/m2)*1 PF-707 (1,390 sheets × 2, 1,850 sheets × 1, 80 g/m2)*1 LU-202 (2,500 sheets × 80 g/m2)*1 |

||

| Paper Weight | Standard | 62 g/m2 to 256 g/m2 *3 (plain, Fine, Colour Specific) 81 g/m2 to 256 g/m2 *3 (Coated) |

|

| Option(MB-506) | 62 g/m2 to 300 g/m2 (Plain, Fine, Color Specific) | ||

| Continuous Copy Count | Up to 9,999 sheets | ||

| Power Source | Inch: AC208 to 240V 21A 60 Hz Metric: AC220 to 240V 20A, 50 Hz / 60 Hz |

||

| Power Consumption | Inch: 4,900W or less (Main body only) Metric: 4,700W or less (Main body only) |

||

| Dimensions [W] × [D] × [H] | 760 mm*4 × 903 mm*5 × 1,073 mm*6 29.92″*4 × 35.55″*5 × 42.24″*6 (Main body + Original Cover) |

||

| Weight | Approximately 291 kg / 641 lb (Main body only) | ||

| bizhub PRESS C1070 | bizhub PRESS C1060 | |

| Type | AIO to the engine (option) | |

|---|---|---|

| CPU | Conforms with main unit specification | |

| Memory | Max. 14 GB Details: 2 GB + 4 GB (Standard of the main body) + 4 GB (IC-602) + 4 GB (UK-104) |

Max. 14 GB Details: 2 GB + 4 GB (Standard of the main body) + 4 GB (IC-602) + 4 GB (UK-104) |

| HDD | Max. 2 TB Details: 500 GB × 3 (Standard of the main body) + 500 GB (UK-104) |

Max. 2 TB Details: 500 GB × 3 (Standard of the main body) + 500 GB (UK-104) |

| Page-description Language | Adobe PostScript3 (PS3019), PDF direct print (PDF version 1.7), APPE (version 2.6) (UK-104 or UK-207 is required), PDF/VT (version 2) (UK-104 or UK-207 is required), TIFF direct print (TIFF version 6 compliance), PPML (version 2.2), PCL-5c compatible, PCL XL (PCL6 version 3) compatible |

|

| Printing Method | Pserver (IPX/SPX), LPD / LPR (TCP/IP), IPP (TCP/IP), AppleTalk (EtherTalk),Bonjour (TCP/IP), Web service printing (TCP/IP), NPrinter / RPrinter(IPX/SPX), Raw Port (TCP/IP), SMB |

|

| Applicable OS | PS Plug-in Windows XP / Server 2003 / Vista / Server 2008 / 7 / 8 / Server 2012*1 MacOSX 10.5 / 10.6 / 10.7 / 10.8 (PPC/Intel) PS PPD*2 Windows XP / Server 2003 / Vista / Server 2008 / 7 / 8 / Serv er 2012*1 Linux CUPS |

|

| Interface | Etheet (1000BASE-T / 100Base-TX / 10Base-T) with IPv6, USB | |

| Scanner Resolution | 200 / 300 / 400 / 600 dpi | |

| Data Format | PDF, TIFF, JPEG, XPS | |

| Driver | HDD Twain Driver, Real Time Mode Twain Driver | |

| Copying process | Electrostatic laser copy |

| Toner system | Simitri® HD Polymerized Toner |

| Copy/print speed A4 | [C759] Colour: Up to 65 ppm, B/W: Up to 75 ppm [C659] Colour: Up to 65 ppm, B/W: Up to 65 ppm |

| 1st copy out time | [C759] Colour: 4.9 sec. or less, B/W: 3.6 sec. or less [C659] Colour: 4.9 sec. or less, B/W: 3.7 sec. or less |

| Warm-up time | Colour: 35 sec. or less, B/W: 22 sec. or less |

| Copy resolution | 600 × 600 dpi |

| Gradation | 256 gradations |

| Multicopy | 1-9,999 |

| Original format | A5-A3 or 11×17 , custom size |

| Magnification | 25-400% in 0.1% steps, auto-zooming |

| Type | Embedded |

| CPU | Conforms with main unit specification |

| Memory | 2 GB |

| HDD | 500GB SATA |

| Page-description Language | Adobe PostScript3 (PS3019),PDF 1.7),PCL 5/6 emulation |

| Printing Method | TCP/IP, SNMP, SMB, FTP, LPR, IPP,Bonjour |

| Applicable OS | Windows XP / Vista / 7 / 8 / Server 2003 / Server 2008*1 MacOSX 10.5 / 10.6 / 10.7 / 10.8 |

| Scanner Resolution | 200 / 300 / 400 / 600 dpi |

| Data Format | PDF, TIFF, JPEG |

| Driver | Twain Plug-in |

*1Including 64-bit versions.