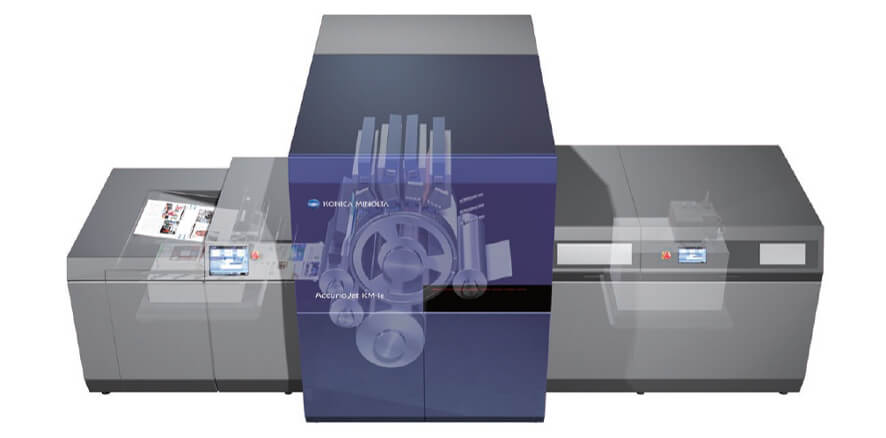

The Accuriojet KM-1e is a digital full color 29.5 inch sheet-fed LED UV Inkjet press that offers print professionals infinite possibilities. With the new KM-1e you will be able to deliver outstanding print output much faster than with offset or aqueous inkjet. Zero make-ready is required and no drying time is needed. Since our UV light curing technology dries ink instantly, your images stay crisp and clean with superior color stability and consistency. With the KM-1e's expanded print job applications, reduced downtime, and greater flexibility, your productivity will be better than ever leading to diverse new projects and increased revenue streams.

Key features

FOGRA53 Certification

Versatile Print Applications

UV Inkjet Technology

Dot Freeze Technology

Providing unlimited print service

AccurioJet KM-1e is compatible with various media such as translucent, metallic, coloured and plastic types by newly adopted media sensors. Now, the advantages of utilization of wide media compatibility of UV ink enables customer to expand their printing services.

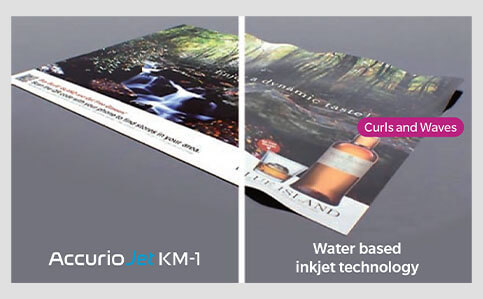

0.06 mm thin media

Capable of printing on thin paper without curling or wrinkling caused by swelling and drying processes required by aqueous inkjet systems.

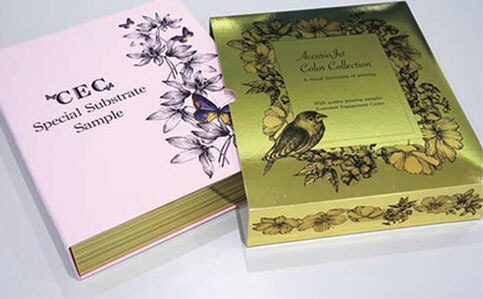

0.6 mm Thick Media

Thick paper printing capability expands the range of printing applications to include items such as packages, tags, table-top calendars or menus, direct-mail and simple photo albums.

Translucent Media

Translucent media printing capability creates new printing services such as backlit posters and signage printing with high image durability.

Synthetic Media

Restaurant menus without lamination, maps, figures and documents for outdoor use can be easily created using the unique UV inkjet technology

Texture & Embossed Media

Business cards, shop cards, invitations, certificates, etc. Combination of UV ink and the non-contact inkjet printing method realizes the best results.

Canvas

High quality printing on canvas is also possible with the UV inkjet system.

Metallic & Coloured Media

The metallic and coloured media printing capability expands printing services for items such as business cards, shop cards and packages.

Clear Film

The clear plastic and film printing capability can be used to add applications such as specialty packages and clear folders as new printing services.

Technologies that support business expansion

AccurioJet KM-1e incorporates Konica Minolta’s unique UV ink and inkjet head. Various technologies have been adopted to maximise the features of the inkjet system and support customers’ business expansion.

UV Inkjet Ink

UV ink, which enables printing on various media including offset stock without the need for pre-coating. Light-curable UV ink reduces damage to the paper, which is often the case with heat drying, thus consistently providing high-quality prints.

Long Life UV Led

UV LED has a longer life and provides highly consistent UV light. The various merits include less damage to the paper because almost no heat is generated, as well as no ozone emissions. LED-UV also offers the advantages of shorter heating and cooling time.

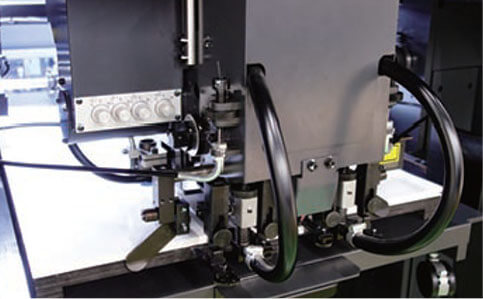

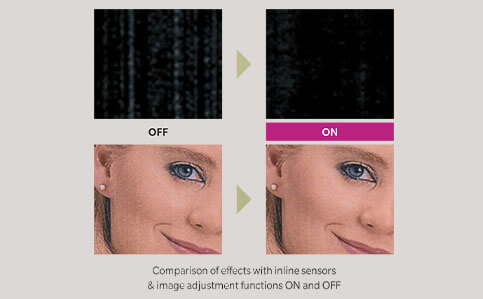

Inline Sensor

Detection of imaging errors by inline sensors ensures consistently high-quality image output.

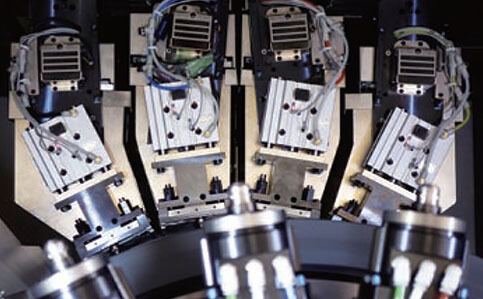

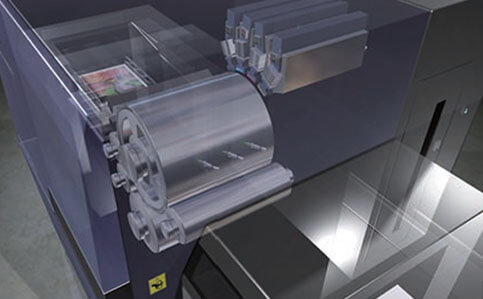

High Precision Inkjet Head

High-density heads with 600 nozzles per inch. Two of these are incorporated into a module to achieve high resolution output of 1,200 dpi.

Inkjet Head Module

The print bar is composed of an array of high-resolution/high-frequency heads. High quality images are reproduced in a single pass at speed as high as 3,000 sheets/hr.

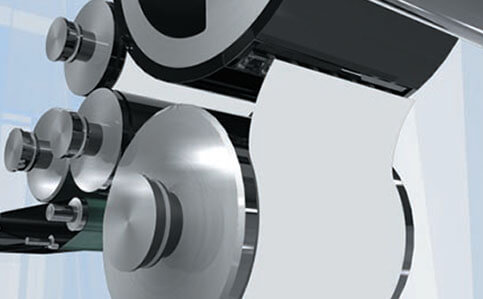

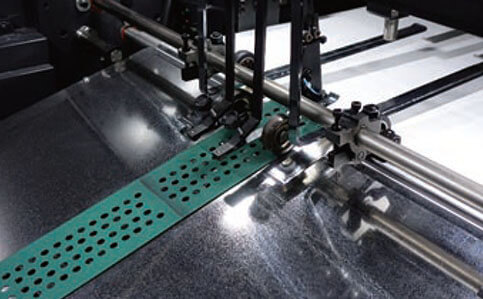

Highly Stable Paper Transport

KM-1e is equipped with an offset-equivalent transport mechanism including functions such as air blower, vacuum suction, dram suction, paper stretch suction and claw grip feeding to ensure unfailing stable paper transport.

New Media Sensor

Various new sensors are adopted for secure handling of new media such as transparent, metallic and coloured types to enable customers to expand their print services.

High productivity for the shortest turnaround

High productivity of 3,000 sheets/hour with the maximum paper size with the auto duplex printing function enables customers to provide the fastest delivery service.

High Productivity of 3,000 Sheets/Hr.

Capable of output of 3,000 sheets/hour/simplex of the maximum paper size (585×750mm) and 1,500 sheets/hour in the automatic duplex printing mode.

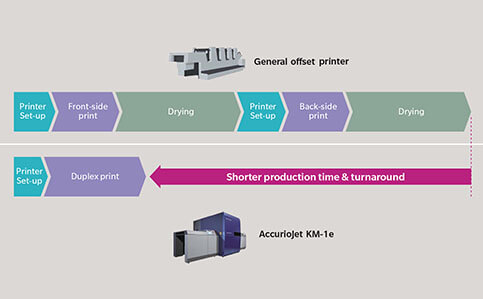

Automatic Duplex Printing with No Drying Time

Capable of automatic duplex printing with no drying time. Elimination of waiting time contributes to reduced overall production time. (Auto duplex printing : 0.06 to 0.45mm thickness)

Wider Media Size Improves Flexibility & Productivity

The wider B2+ size, 585×750mm, enables flexible imposition to achieve even higher productivity

Machine Design That Minimises Downtime

The machine is designed to be maintained by the operator. This means reduced downtime caused by visits by service engineers, contributing to improved operating ratio.

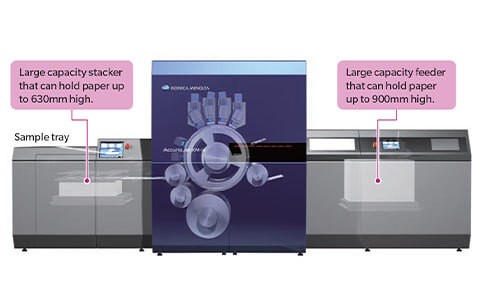

Large Capacity Paper Feed / Stack Systems for High Volume Runs

The feeder can accept paper up to 900mm high and the stacker up to 680mm high. In addition, a sample tray is equipped for quality checks or small lot printing.

Outstanding Overall Productivity for the Shortest Turnaround

Elimination of the need to make and set plates in the press ensures shorter set-up time and the auto duplex printing capability realizes outstanding overall productivity.

Superb reliability & consistency

Reliably produces printed products of stable high quality. AccurioJet KM-1e uses paper handling technology identical to that in an offset printer to ensure reliable and stable paper handling. In addition, the use of UV ink ensures highly-accurate registration and minimal nozzle clogging to deliver stable image quality

Superb Colour Consistency

Allows perfect colour matching of jobs with repeatable results within a tolerance of ΔE 1.5. This patented process ensures perfect inkjet operation, allowing jobs to be instantly moved to finishing, thus saving time and money

Greater Registration Accuracy

The use of UV ink eliminates problems such as waviness or curling commonly occurring during processes such as thermal fixing and drying to achieve superb print quality and highly-accurate registration.

Paper Handling Technology Identical to Offset Printing

AccurioJet KM-1e is fully equipped with an offset-equivalent transport mechanism including functions such as air blower, vacuum suction, dram suction, paper stretch suction and claw grip feeding to ensure stable paper transport and highly accurate registration.

Image Quality Control by Inline Sensor

AccurioJet KM-1e is furnished with an internal inline sensor that automatically detects and corrects image flaws. The inline sensor minimises image quality degradation caused by nozzle defects in the inkjet system.

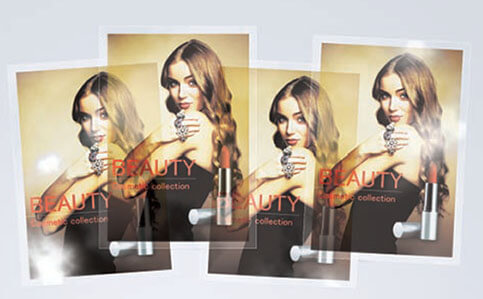

Outstanding image quality

New high-definition print heads provide top image quality of 1200 dpi to create effects such as superb skin tone with less graininess and a natural-gloss look.

1200×1200 dpi High Image Quality

Konica Minolta’s cutting-edge inkjet print head, unique UV ink and half-tone processing technologies achieve 1200dpi high image quality.

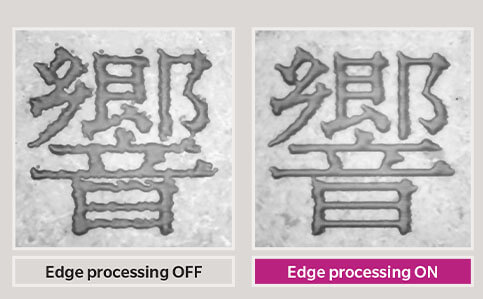

Sharp Text Quality

Konica Minolta’s original proprietary font edge-processing technology realizes excellent text quality with sharpness and legibility even for small font sizes.

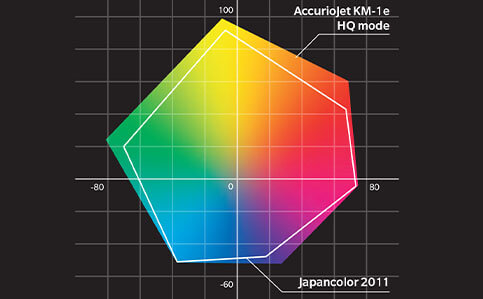

Wide Colour Gamut

The wide color gamut sufficient to cover Japan color standards ensures accurate colour reproduction.

World’s 1st Fogra53 Accreditation

Konica Minolta has become the world’s first press manufacturer to achieve the ‘robust’ FOGRA53 profile certification. AccurioJet KM-1 achieved this accreditation after completing an exhausting testing program.

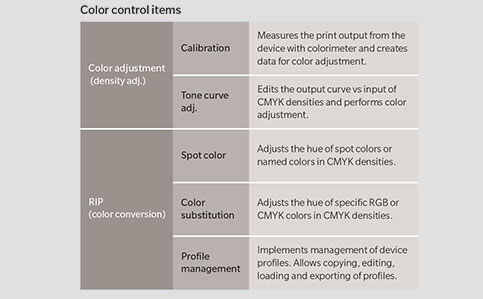

Highly Functional / Accurate Colour Management System

Use of color management software provides consistent color reproduction.

Accurate Registration and Print Quality

Use of UV ink helps avoid waving and curling of the paper often caused by heat fixing and drying required for aqueous inkjet systems and provides high quality prints with high registration accuracy.

Optimised Ink Volume to Match Paper and Printing Objectives

In addition to the standard mode, two print modes are available for selection of coated paper that requires high quality image or uncoated paper that requires matte texture.

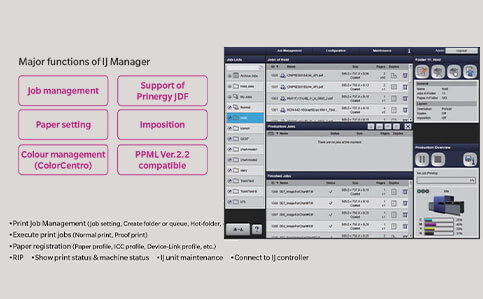

Excellent operability for efficient workflow

Enhanced data processing system “IJ Manager”, a system easily incorporated into existing offset workflows, newly developed interface for inline connection with various types of post-press equipment, newly adopted tape inserter to improve work efficiency in post-press operation.

IJ Manager

The system incorporates a high-speed RIP for full VD processing, sensors to detect the nozzle jet status and an algorithm to compensate for defective nozzles on the fly.

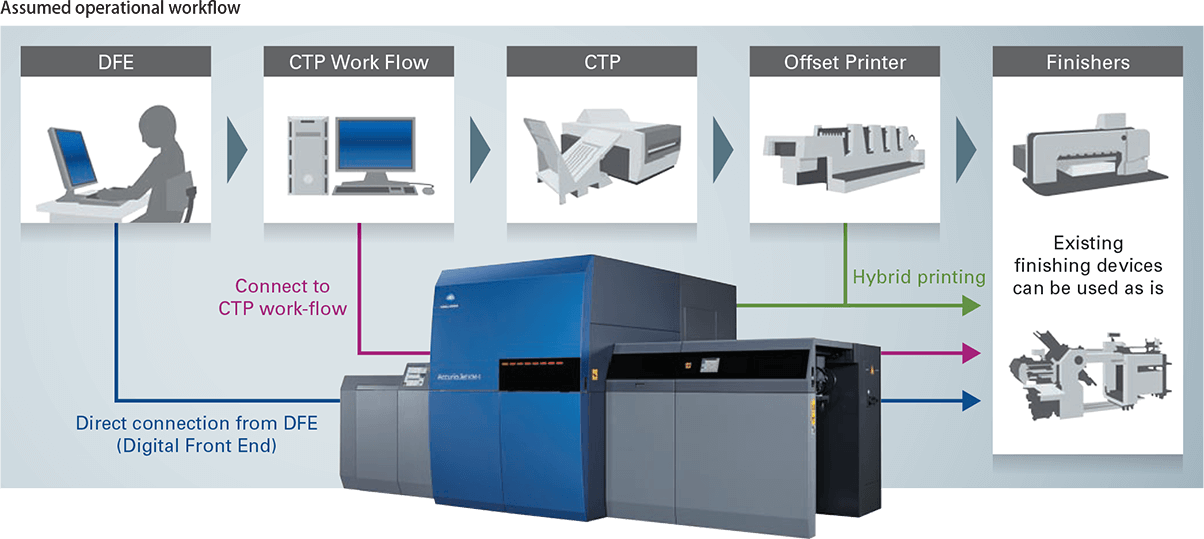

Supports Hybrid Printing

KM-1e is capable of outputting prints receiving files from general DFE (Digital Front End) or CTP workflow RIP and supports hybrid workflows where the user can freely choose between offset printing and digital printing as required.

Variable Data Printing

Compatible with PPML 2.2, KM-1e helps to create new business not possible using offset printing.

Newly Adopted Tape Inserter

Automatically inserts tape between jobs to improve work efficiency of post-press operation.

Inline Interface for 3rd Party Post-Press Equipment

Post-processing can now be completed in-line with a newly developed interface to improve work efficiency and facilitate short turnaround.

| Type | 29-inch Sheet-fed full colour UV inkjet digital press |

| Output resolution | 1,200 x 1,200 dpi |

| Ink | UV curable ink (4colours / C, M, Y, K) |

| Print speed | Simplex printing: 3,000 sheets/hour Duplex printing: 1,500 sheets/hour |

| Paper size | Maximum : 585 x 750 mm |

| Max. printable area | Simplex printing: 575 x 735 mm Duplex printing: 575 x 730 mm |

| Paper thickness | Simplex printing: 0.06 to 0.6 mm Duplex printing: 0.06 to 0.45 mm |

| Paper type | Uncoated paper, Coated paper. Art coated paper. Coloured paper, Metallic paper. Transparency media. Plastic media. Canvas, Stone paper |

| Data format | PDF Ver. 1.7, PDF/X 1a.3.4.5, PDF/VT-1, TIFF Ver.6 compliant, PPML Ver.2.2 |

| Print mode | Rich (Japan color supported mode) Standard Economy (Ink saving mode) |

| Power source | 3 phase 200V 335A (50Hz/60Hz) |

| Device dimension (W x D x H) | Main body + Feeder + Delivery + Ink delivery unit: 5,369 x 2,947 x 2,325 mm |

| Device weight | Main body: Approx. 8,100 kg Ancillary facility: Approx. 2,000 kg |

*Specifications and functions listed in this catalog are subject to change without notice.