Rethink label printing with AccurioLabel 230.

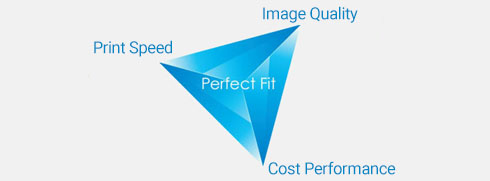

A digital label printing system that offers enhanced productivity, job flexibility, operability and excellent image quality with affordable system cost, is a perfect fit for business expansion and parallel use with existing analog presses. The benefits of digital label printing are clear: fast turnaround, no plate making, high profitability and skill less operations.

Key features

Productivity

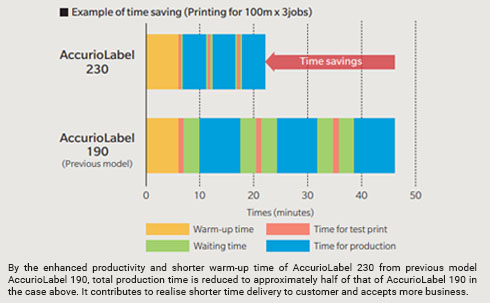

Shorter warm up time and print speed of 23.4 m/min on tack paper

Performance

Continuous printing upto 1000 M

Compact footprint

High performance in compact system

Instant production

Short lot digital label print applications

Just the right size “ Perfect Fit ” label printer

“AccurioLabel 230” has been created to take center stage on the globally-expanding digital label market.

A digital label printing system that offers enhanced productivity, job flexibility, operability and excellent image quality with affordable system cost, is a “Perfect Fit” for business expansion and parallel use with existing analogue presses.

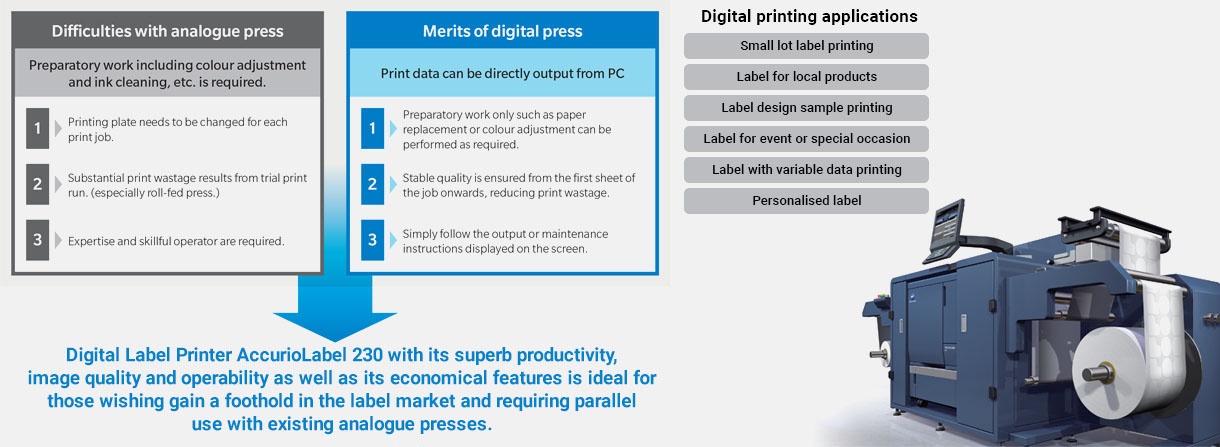

Digital label printing

Merits of introducing digital printing

Print jobs of various kinds and short-run jobs are increasing compared to long-run jobs of the past and printers are required to cope with orders with a quick turnaround. Taking advantage of the flexibility of digital printing, these orders that are difficult to handle with an analogue printing press can now be handled efficiently. In addition, values can be added to the print product using VDP or numbering, which helps differentiate the user among ever-diversifying market needs.

Applications realised by AccurioLabel 230 to meet a wide range of diversifying needs

Enhanced productivity & flexibility

To meet demands of digital printing business such as shorter turnaround and expansion of print application,AccurioLabel 230 improves overall productivity and job acceptability especially overprinting capability on pre-printed transparency or coloured media.

Fast print speed up to 23.4m/min.

Most of tack papers and tack films can be printed with the maximum print speed of 23.4m/min. The print speed enhanced from previous model realises faster turnaround time and contributes to expand the printing business.

Short warm-up time

Warming-up time from job to next job is minimised by no turning off of fusing unit. It not only improves overall production efficiency by the minimum job switching time, but also minimise the paper waste.

Long continuous printing up to 1,000m

Accepting larger size production without switching time and paper losses. When the toner coverages is low, a print mode that adds colour belts on both sides of paper is available for the long length printing that supplies necessary amount of toner to keep the developer fresh. The colour belts are not necessary when the toner coverage is 3.5% or above.

Mouse-compatible operation panel

The large 15-inch display adopted is easy to view and operate. The angle of the panel can be freely adjusted to suit the user and the easy-to-understand GUI and guide messages ensure high operability when making settings. A USB mouse can also be connected to improve operability.

Wide media compatibility without pre-treatment

Thanks to digital toner HDE and Konica Minolta’s low-temperature fixation technology, AccurioLabel 230 is compatible with a wide range of media including not only ordinary and matte paper, but also glossy paper, tack paper and film essential for label production. The user can not only select the ideal media to match applications but also print labels without the need for preprocessing.

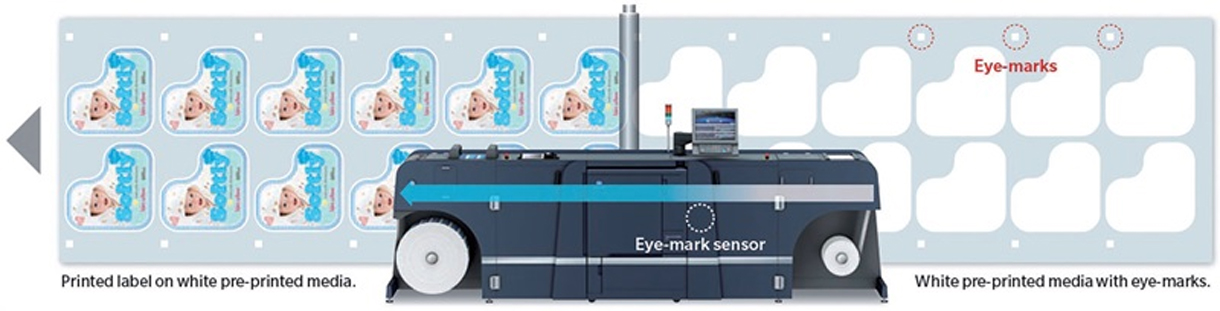

Over printing capability with accurate registration

Over printing kit (Optional) is provided to enhance the usability. It enables digital 4-colour printing on pre-coated media with accurate registration that is realised by newly adopted eye mark sensor.

Food grade safe toner

The toners of AccurioLabel 230 are in compliance with FDA standards by the evaluation of the authorised organisation considering the safety of indirect food packaging label.

*The FDA standard is stringent safety standards to the potential product that consumers are in contact with food, pharmaceutical and cosmetic by FDA (Food and Drug Administration).

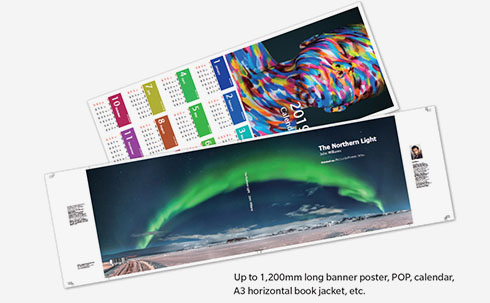

Banner printing capability

As well as store decoration and floor POP displays, the system can be used for long posters, signboards and an extensive range of other applications. The ability to offer promotional proposals with media mixes combined with labels also contributes to business expansion

Excellent & consistent quality

High image quality is realised by Konica Minolta’s unique technology through faithfully facing the high-level needs in digital print market. Colour fluctuation is controlled within the minimum under various condition, which ensures stable and beautiful finish for the first through to the last prints. High image quality that brings higher value of printed material generates advantages for the print services.

High resolution 3,600 (equivalent) × 1,200dpi × 8bits

Combined with the reproductive capability of digital toner HDE, small characters and fine lines can be printed clearly and colour images beautifully output in rich gradations.

S.E.A.D. V

Enhanced Konica Minolta’s Image processing technology S.E.A.D. V backed up with new generation of image processing ASIC and fully automated colour adjustment functions promise to provide print products with the best quality.

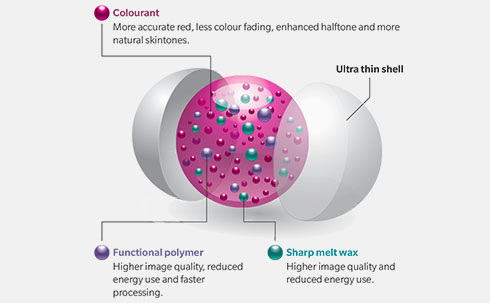

Simitri HDE toner

A 3D hybrid structure that contains functional polymers ensures a high level of compatibility with various types of media and enables realisation of ideal natural textures. In addition, it requires only asmall amount of heat for fusing, significantly reducing power consumption.

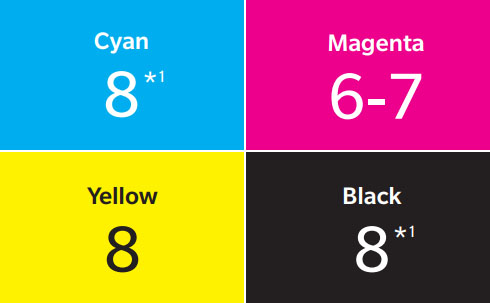

Remarks: The evaluation criteria is classified into 8 levels (1 to 8 levels),and the higher the value, the higher the lightfastness.

*1: The test results indicate that the lightfastness of Cyan and Black toner is ranked as 8 or higher

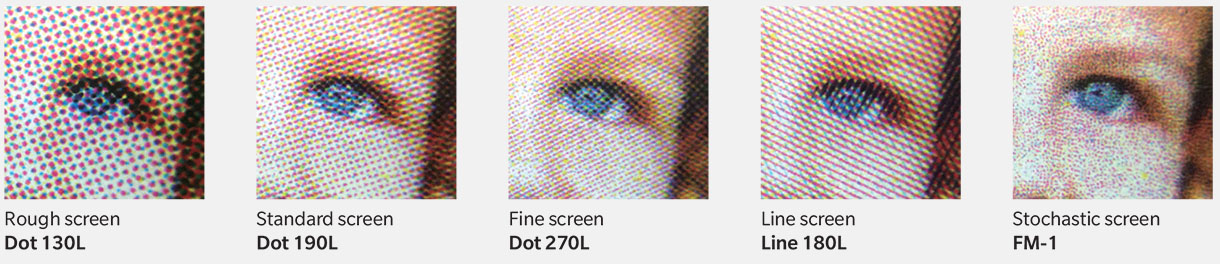

High quality screens

Equipped with a total of 12 types of screen, 6 dot screens, 3 line screens and 3 stochastic (FM) screens, the system can be matched to applications and purpose such as proof output, photograph printing and moire suppression.

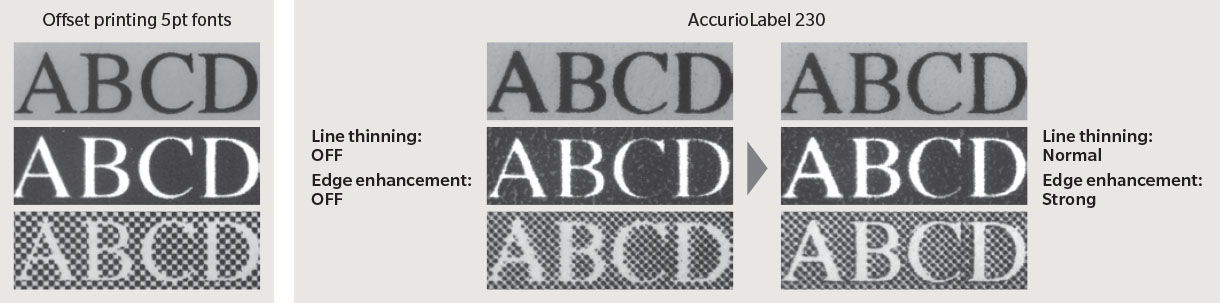

Line thinning & edge enhancement technologies

Furnished with a precise outline processing function that reduces blurring and streaking to realise high quality even for colour or outline characters.Characters on food or ingredients labels, for example that tend to be small, or barcodes can be printed clearly.

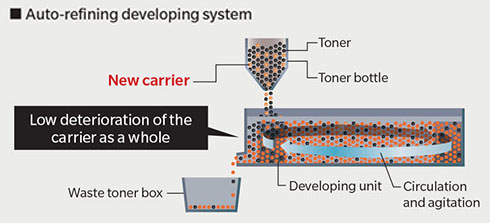

Auto-refining developing system

A new carrier is supplied together with the toner to refresh the carrier in the developer, stabilising the developer condition to maintain high image quality throughout the system lifetime. The longer developer life also minimises downtime

Outstanding operability

Compared not only to flexography but also liquid development and inkjet printers, AccurioLabel 230 ensures ease of maintenance. Tasks that take time on analog machines such as color adjustments can be performed with ease on a digital machine. The ability to perform operations simply by following on-screen instructions makes it possible to operate the machine with little time needed for training.

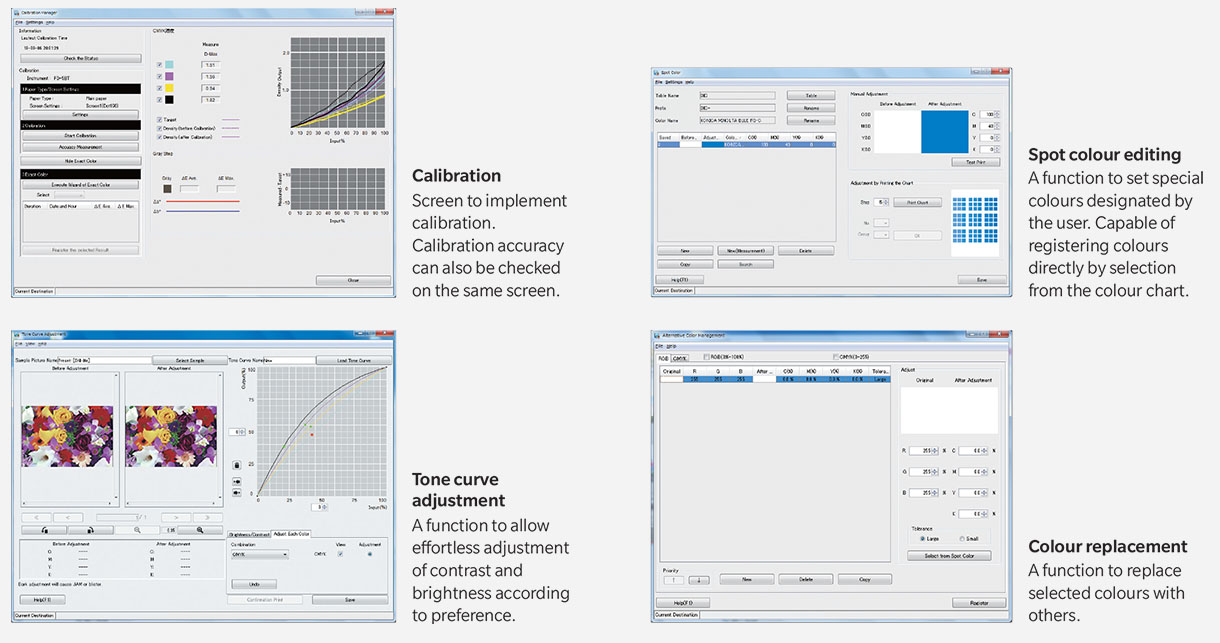

Color Centro

Equipped with colour management software as standard, allowing operation, editing and setting for colour correction, colour profile creation, etc. that best suits the digital press used.

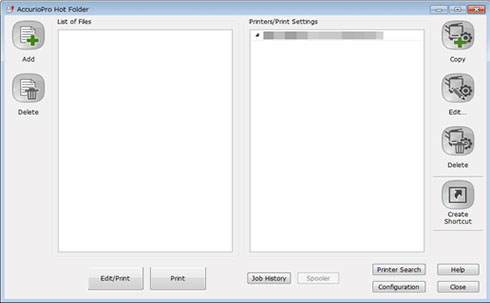

AccurioPro hot folder

AccurioPro Hot Folder allows you to directly print a PDF or TIFF file without starting an application. You can also preset the job settings and reduce the burden of making print settings.

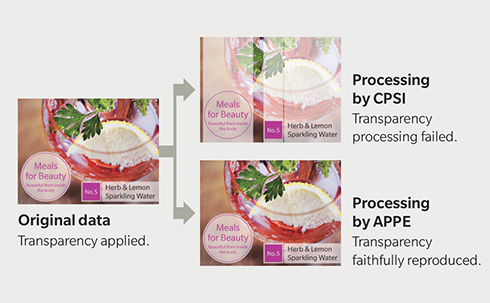

APPE 4.6

Equipped with Adobe genuine APPE 4.6. Capability of directly printing PDF files without using the print driver enables faithful reproduction of transparency. Optional UK-218 (APPE kit) required.

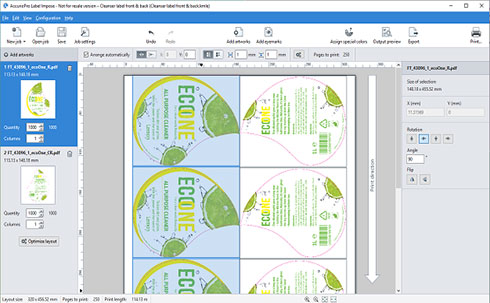

AccurioPro label impose

The AccurioPro Label Impose software tool provides the perfect solution. The application not only gives operators a simple and intuitive interface to automatically impose and prepare label jobs for printing. At the same time, the software also enables users to create PDFs as basis for the corresponding cutting tools on the die cutting equipment. Working seamlessly with the AccurioLabel 230, AccurioPro Label Impose perfectly complements Konica Minolta’s label press!.

| Type | Console | |

| Print method | Dry toner electrophotography | |

| Colour support | Full colour (CMYK) | |

| Printing resolution/gradation | 3600 dpi (equivalent) × 1200 dpi / 8 bit | |

| Printing image size | 90 × 115 to 320 × 1,195 mm | |

| Paper width | 250 to 330 mm | |

| Paper thickness range | 81 to 256 gsm (80 to 250 μm) | |

| Print media | Non tack paper ( 81 176 gsm ), tack paper (136 256 gsm ), Tack coated paper G/M (136 256 gsm ), Tack S yntdetic paper ( 136 176 gsm ), Tack PP (136 176 gsm ), tack PET (136 216 gsm) |

|

| Print speed | Speed range | Max.:23.4 m/min; High : 18.9 m/min; Middle: 13.5 m/min; Low: 9.45m/min |

| By media weight | 81 to 176 gsm : Max. 23.4m/min. 177 to 256 gsm: Max . 18.9m/min |

|

| Compatible file formats | PS, PDF (APPE supported), 8 bit TIFF | |

| VDP file format | PPML, PDF-VT | |

| Power source (single phase) | Metric: 220 to 240 V 50/60 Hz, 25 A Inch: 208 to 240 V 60 Hz, 24 A |

|

| Copy Speed (A4) | Colour/B&W: 55 ppm | |

| Max. power consumption | Metric: 6,000 W, Inch: 5,760 W | |

| Dimensions (WxDxH) | 1,200 × 903 × 1,478 mm | |

| Weight | 292 kg | |

*Specifications and features of the delivered product are subject to changes.

| Maximum roll size | ∅600mm | |

| Power requirements | phase 380V, 20A, 50/60Hz | |

| Print media | Paper: tack paper, Non-tack paper Film: tack film (Synthetic paper, PP, PET) , etc. |

|

| Dimensions (W × D × H) | 3,550 × 2,470 × 1,540 mm | |

| Weight | Winding unit: approx. 423kg Unwinding unit: approx. 446 kg Platform: approx. 335 kg |

|

| Type | Embedded (AIO) type Equivalent to IC-605B witd UK-104 |

|

| CPU | Intel Core i5 4570S 2.9 GHz (CPU in printer) | |

| Memory | System memory 16 GB | |

| HDD | 1 TB × 3 + 500 GB × 1 | |

| Network | 10/100/1000 Base-T | |

| PDL language | PostScript 3 (CPSI 3020), PDF Ver.1.7,TIFF Ver.6 Compliant, PPML Ver.2.2, PCL5c equivalent,PCL XL (PCL6 Ver.3) equivalent, APPE Ver.4.6*1,PDF/VT Ver.2*1 |

|

| Protocol | TCP/IP, NetBEUI, IPP, WSD, SMB, Bonjour | |

| OS applicable | Windows 7, 8.1, 10 Windows Server 2008/R2, 2012/R2, 2016, 2019 (Includes 64 bit versions) Mac OS X 10.9, 10.10, 10.11, 10.12, 10.13, 10.14 |

|

| Main fonts | Adobe 136 fonts, PCL 80 fonts | |

| Driver | PS Plugin driver | |

| Konica Minolta applications applicable | PS web connection, PS net care device manager, color centro, AccurioPro hot folder | |

*1 UK-218 (Option) required.