and creating new ways of working in processing

TRIMMER UNIT

TU-510e

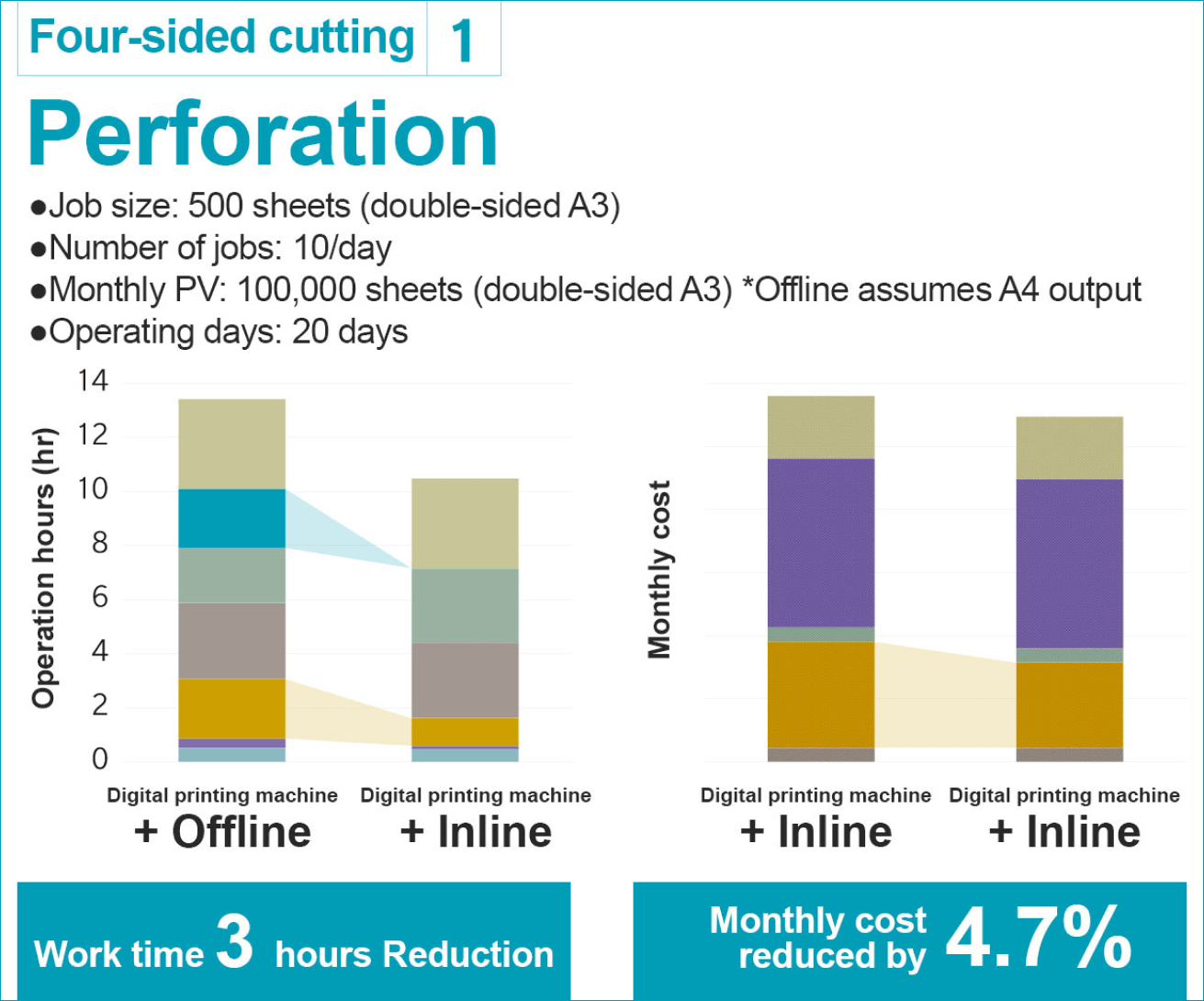

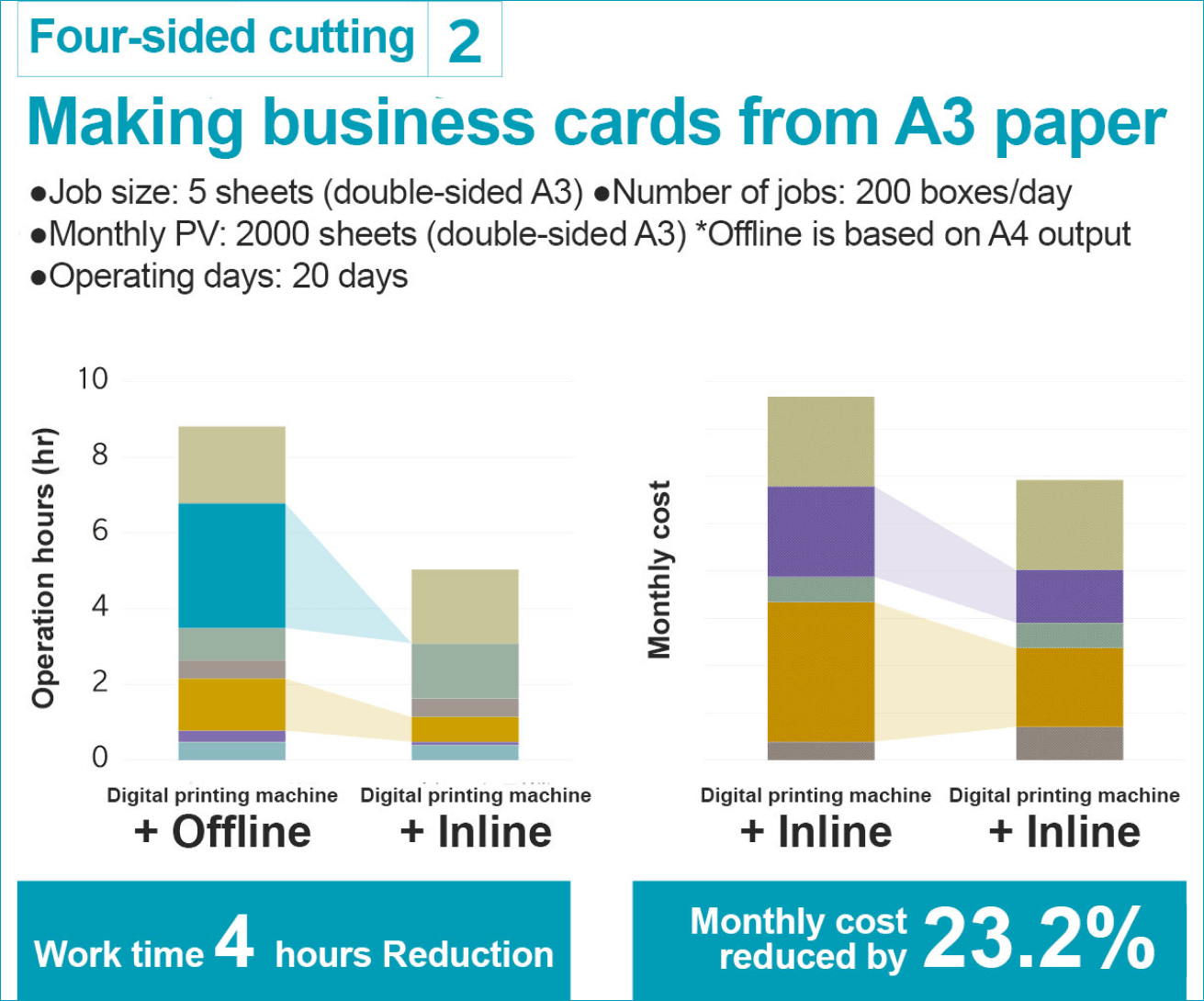

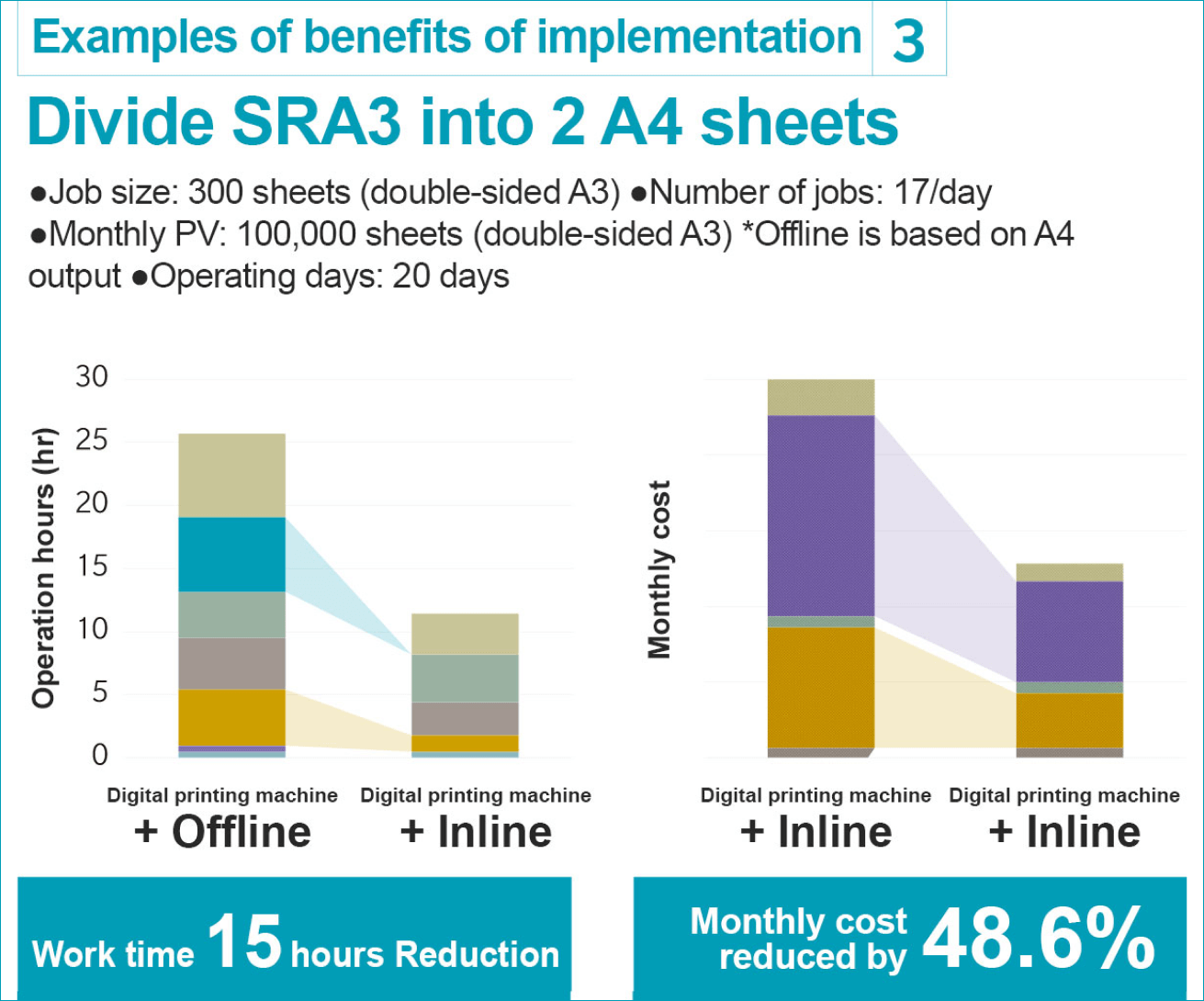

Our proprietary technology automates specialized operations that require "manpower and expertise," reducing the burden on the field and the amount of work time required, thereby contributing to the creation of a profitable environment.

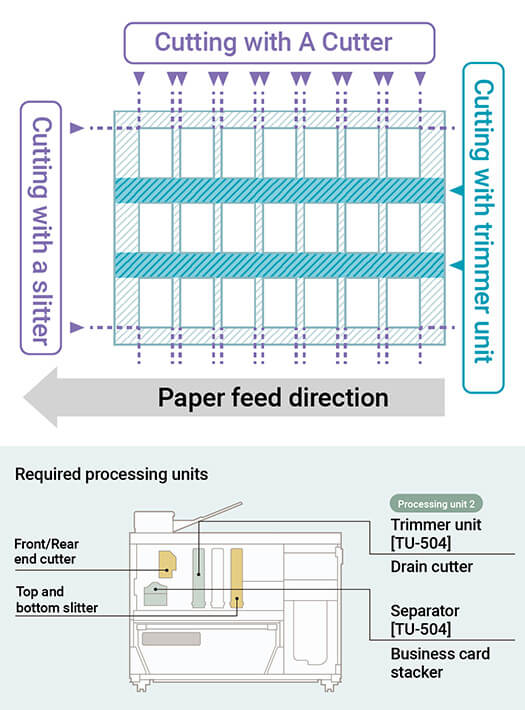

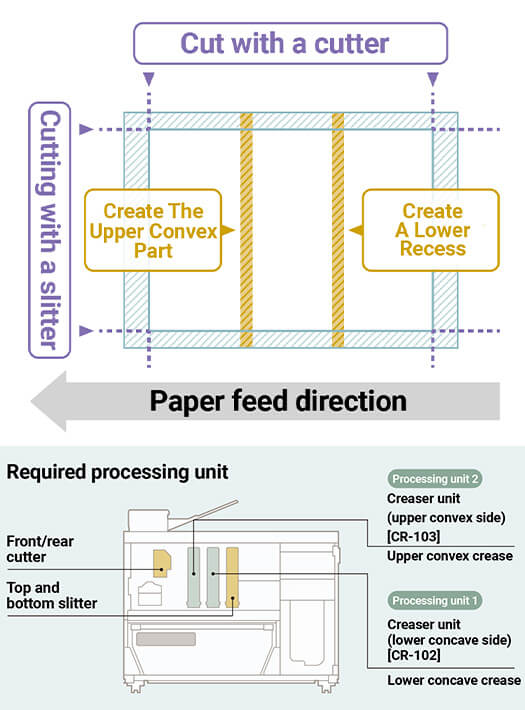

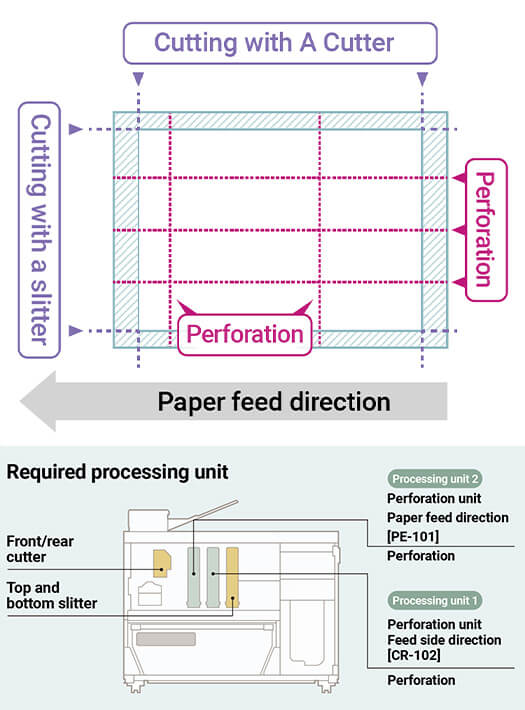

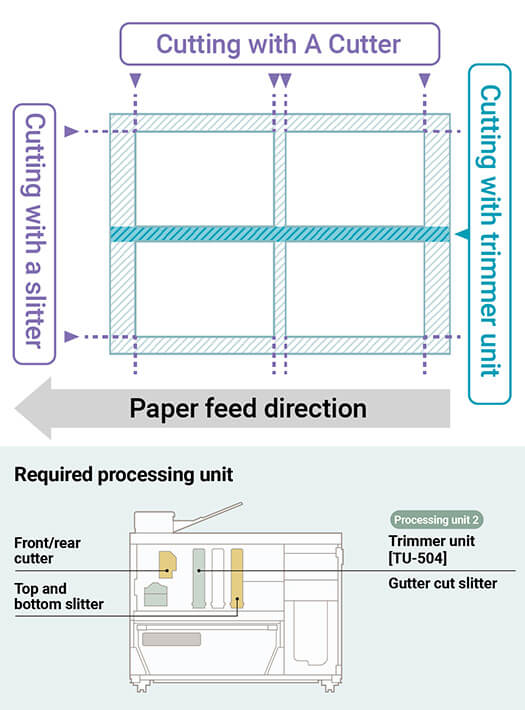

Download BrochureDownload SpecsheetEquipped with technology that automatically processes a variety of processes such as four-sided trimming, creasing, business card cutting, gutter trimming, and perforation.

Processing that previously required specialized equipment and skills can now be done at any printing site by combining standard and optional processing units. It streamlines and innovates the workflow that previously required dedicated personnel and multiple processing devices.

The TU-510e can perform various processes with high performance without manual intervention. This allows for stable quality prints to be produced in a short time, reducing the burden On workers. In addition to reducing labor costs by Shortening work hours, using A3 paper for business cards and two-part jobs also reduces printing costs such as paper and counter fees compared to when using A4 paper.

*The listed operation time and monthly costs are reference values calculated independently by Konica Minolta and may vary depending on the skills of the operator and the measurement environment.

A profile creation tool is available for issuing processing instructions on the TU-510e. Detailed settings can be made with an intuitive UI

You can specify the TU-510e processing settings from the printer driver and send print instructions. The profile must be prepared in advance.

Adjustments to the TU-510e's accuracy and other parameters can be made via the main panel.

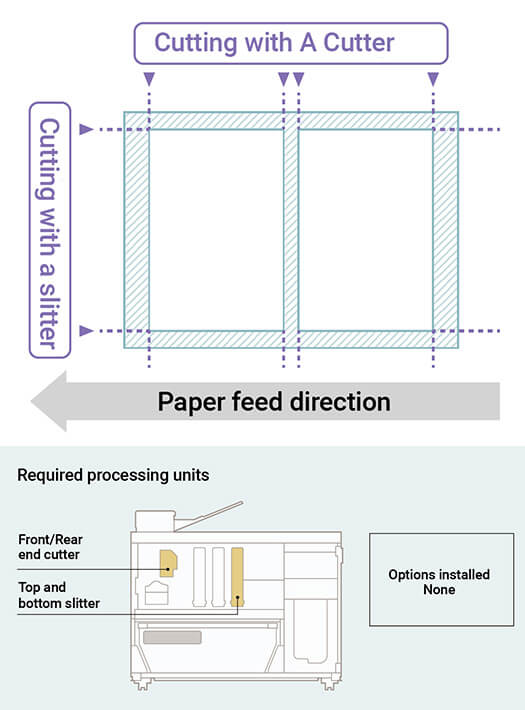

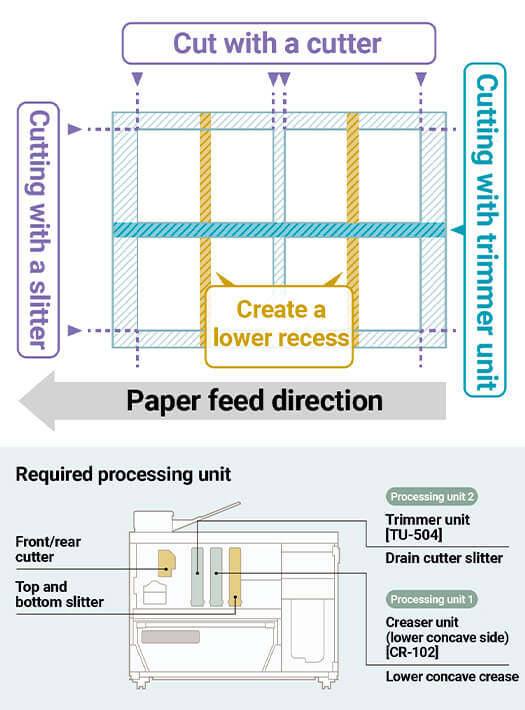

Processing such as four-sided cutting, creasing, business card cutting, and gutter trimming can be performed with high performance and without human intervention, reducing the burden and time of workers with stable quality.

The TU-510e can be operated by the same members of the printing team. Therefore, even if you are unable to secure a dedicated person, there is no need to search for dedicated personnel.

Since it can be installed and managed as an option for the printing machine, there is no need for special rules or dedicated space.

By combining standard functions with optional processing units, a wide range of processing can be achieved with one unit, eliminating the need for multiple processing machines, and eliminating the need to purchase or manage them.

As an option for the printing machine, in-line processing is possible, so cutting and printing can be done at the same time. This eliminates the need for workers to carry paper.

The machine is designed to be inaccessible to humans, and cutting and scoring are performed inside the machine. This means that workers do not come into contact with the blade of the cutting machine, avoiding danger.

The TU-510e allows you to select and install the processing units you need, allowing you to create the perfect machine for your business.

For inquiries and questions regarding TU-510e,