Printing your memories and experience a new world of expressions with high chroma printers. The wide colour gamut of AccurioPress C83hc/C73hc high chroma toner expands new printing business opportunities.

Key features

Excellent versatility

Wide paper weight compatibility up to 350gsm

Enhanced light blue/green/pink/purple/magenta

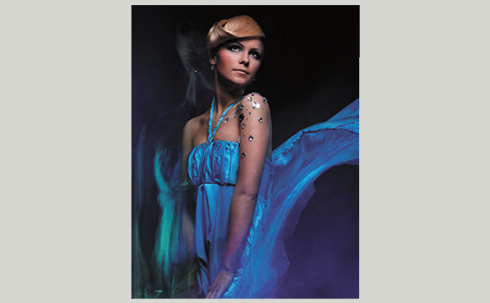

Makes it possible for photographer, graphic designers to create eye-catching albums, posters and POP

Applications

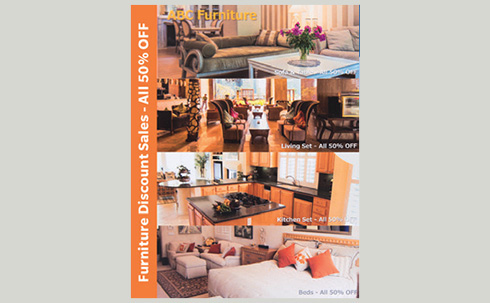

The expansion of spot colour reproduction is useful for printing company logos, POP with high impact, packaging and poster creation

Applications

By utilising the wider colour gamut, colours closer to RGB can be obtained. That is good for studio photo, photo book, nature photo, illustration, CG, web to print and so on. The printed image will be more natural and impressive compare to image that is created with ordinary CMYK system. The expansion of spot colour reproduction is useful for printings with

company logo colours and the vivid and strong colours can be utilised to create impactful POP, package, poster and so on that makes big.

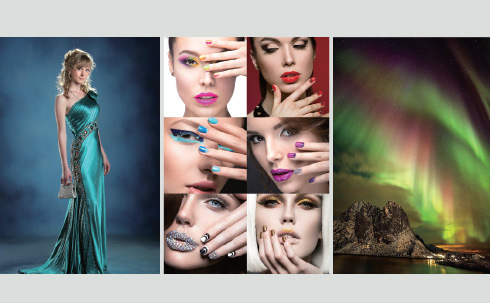

Studio Photographs, Photo Books, etc.

The wide colour-gamut toner used by AccurioPress C83hc/C73hc utilises colour materials featuring greater saturation and brightness than conventional CMYK toners

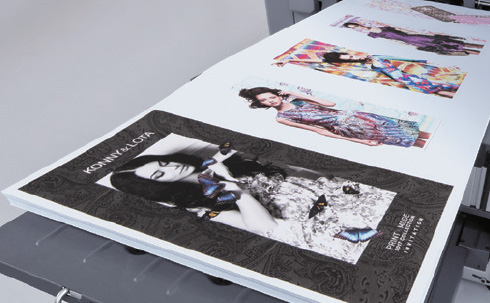

Nature Photographs, Apparel Catalogues, etc

Addition to the conventional CMYK colour gamut, one of the greatest features of AccurioPress C83hc/C73hc is its ability to reproduce colours difficult to realise using a CMYK printer such as sunset purples, the pink of flowers, high-key greens and blues. This makes it possible to express the intent of photographers and designers, for example, with greater fidelity in prints. Moreover, prints of items such as apparel catalogues or fashion photographs can be supplied with colours close to the originals.

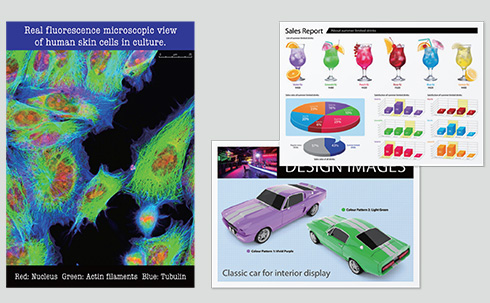

Academic Reports, Analytical Photographs,CG, Office Documents, etc.

Because images seen on screen, such as office documents and CG, are configured with RGB, some colours cannot be reproduced with conventional CMYK printers because they have a narrow colour gamut. High Chroma Toner, however, is capable of reproducing colours closer to the image seen on screen and thus also demonstrates its prowess for presentation documents.

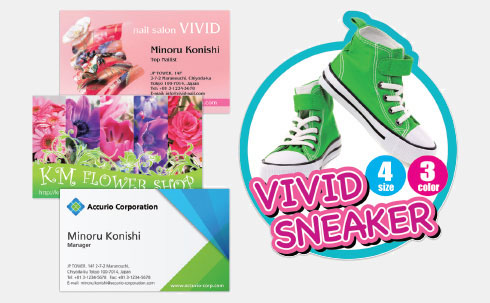

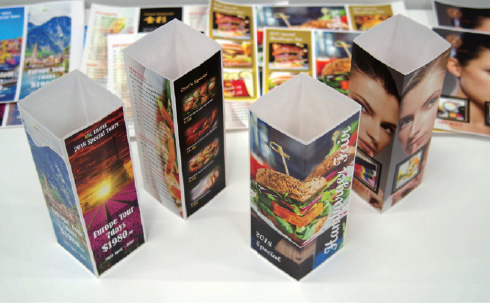

Business Cards, Shop Cards, POPs, DM, etc.

The excellent spot colour reproduction with the wide colour gamut provides bright and clear company logo colours for name card and shop card especially for light blue and green. AccurioPress C83hc/C73hc provides the capability to create items such as impactful business cards or POPs using colours not often seen. AccurioPress C83hc/C73hc enables utilisation of colours that users have hesitated to use in printing up to now, realising the ability to supply distinctive printing services. Moreover, differences between colours on monitor screens and prints can be minimised when approaching customers with DMs or cross media.

Designs, Illustrations, Coterie Magazines, etc.

Wish to use impactful colours on packages, but hesitate to do so because such colours cannot be produced with ordinary printing. At times like this, with AccurioPress C83hc/C73hc, small lots can be printed with abundant colour reproduction and high productivity using preferred colours. Prints faithfully reproduce the colours that satisfy the creator’s particular preferences for animation drafts, illustrations or coterie magazines featuring a wide variety of colours such as purples and bright greens.

Regular Prints, Catalogues, etc.

Because it also covers most of the CMYK colour gamut, High Chroma Toner enables the creation of beautiful prints of ordinary CMYK files with ease simply by applying CMYK profiles.

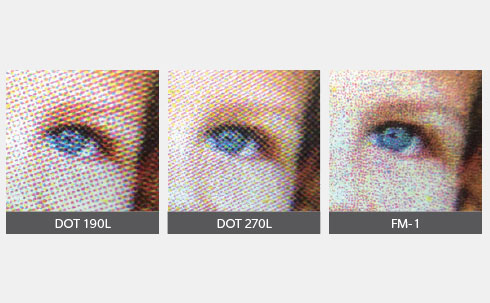

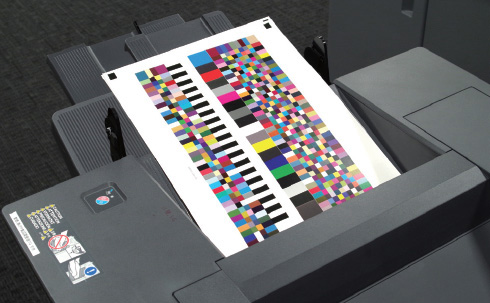

Various screens and smooth gradation owing to sophisticated dot control

Best suitable screen can be selected from various screens available for AccurioPress C83hc/C73hc. Dot screen x 6 types, line screen x 3 types, FM screen x 3 types, total 12 screens are available for choice depending on the application or purpose.

Power of colour reproduction

Colours seen on displays or images shot using a digital camera can express a wider colour gamut than CMYK used for ordinary printing. For this reason, because CMYK ink or toner has a narrow colour gamut of colours such as pink, purple and bright green, colours tend to become dull or muddy when printing RGB images. As the world’s only printer that uses a new toner free of the restrictions imposed by the colour gamut of ordinary toners, AccurioPress C83hc/C73hc offers a solution to such problems.

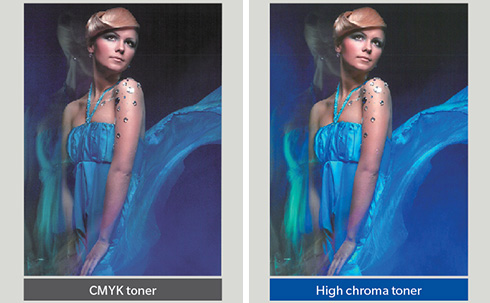

Actual printed images scanned by bizhub MFP. The difference between the two colours may not be seen or smaller when this document is printed with standard CMYK printer.

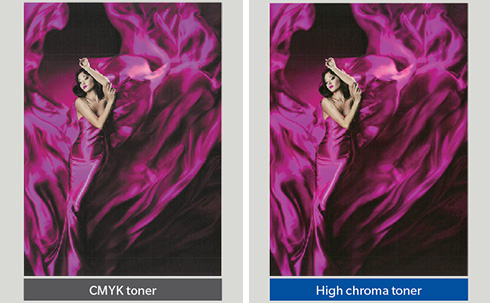

Actual printed images scanned by bizhub MFP. The difference between the two colours may not be seen or smaller when this document is printed with standard CMYK printer.

Enhanced light blue/green

With combination of the wider colour gamut and higher L* value of high chroma cyan toner than that of CMYK toner, clear and bright colours can be maintained especially for bright blue and green. CMYK toner loses the colour when the toner amount is reduced to express the brightness or loses the brightness when the colour is tried to be maintained.

Actual printed images scanned by bizhub MFP.

Actual printed images scanned by bizhub MFP.

Enhanced pink/purple/magenta

By utilising high chroma magenta toner, vivid and clear pink and purple colours can be obtained. The large colour difference between CMYK printing and RGB colours in monitor has been one of big weak point of CMYK printing systems. For example, flowers with pink or purple colour is always dull and muddy compare to colour expected. Graphic designer and illustrator sometimes have to give up to use these colour they want use. High chroma toner get rid of the restrictions. The high L* value helps to create smooth and less graininess skin tone that is good for photo related applications. Also, the vivid colour make possible to create eye-catching poster, POP and so on that makes big differentiation from other printers.

Print profiles to utilise features of the high chroma toner

With “Saturation mode” of AccurioPress C83hc/C73hc, the maximum colour space of high chroma toner is utilised and customer can experience the new world of colour reproduction that has never realised with ordinary CMYK systems. Of course, C83hc/C73hc can print with ordinary CMYK colours with “Standard mode” because the high chroma toner covers most of colour space of CMYK toner. So, the customer can make print products with normal CMYK colour or high chroma colour with one system.

CMYK toner

“Standard mode” for RGB image

The colours outside of CMYK colour space is narrowed to colours that CMYK toner can reproduce. Some highly saturated colours are not reproduced and lost.

High chroma toner (C83hc/C73hc)

“Standard mode”

The printed colours are close to result printed with CMYK toner. However, light blue, green and pink areas are more vivid and clearer than that produced by CMYK toner.

High chroma toner (C83hc/C73hc)

“Saturation mode”

With “Saturation mode”, maximum colour space of the high chroma toner is utilised. The colours are more brilliant, clear and impactful.

High chroma toner (C83hc/C73hc)

“Soft mode” (IC-605 only)

“Soft mode” is provided to improve reproducibility for shadow area, when the quality is not satisfied.

CMYK toner

“CMYK profile” (ex. Japan Color)

Normal CMYK colour.

High chroma toner (C83hc)

“CMYK profile” (ex. Japan Color))

Normal CMYK colour. The quality is very close to that of CMYK toner.

Superb Colour reproduction with high performance

Superb colour reproduction

Automated adjustments

High productivity

C83hc*/C73hc**

Excellent versatility

High productivity

Productivity – Max. 81ppm/A4*

The productivity of C83hc is enhanced from 71ppm/A4 of C71hc to 81ppm. Paper weight for the rated speed is also improved from 62 to 176gsm of C71hc to 62 to 216gsm.

Saddle-stitcher SD-513

The [SD-513] is a saddle-stitcher that is capable of saddle-stitching of 300gsm thick paper (max.12 pages) in addition to volume pages up to 200 pages (64gsm paper for body pages). Expanded functions enable realisation of a highly-polished finish comparable to bookbinder used for offset printing. The booklet-shifting type stapling mechanism is capable of 4-point stapling and is also furnished with functions for such tasks as edge-trimming, multi centre fold and multi tri-fold.

Mounting a Spine Corner Forming Unit [FD-504], it is possible to create spine corners, which provide a high quality finish by reducing swelling of saddle-stitched booklets. Flat-shaped bookbinding also leads to reduction of work space and workload in transportation.

Use of Trimmer Unit [TU-503] makes it possible to trim both the top and bottom edges of the sheet. Output of full bleed designs is made possible in hybrid use with a fore-edge trimming function that is standard equipment.

Use of an optional Creaser Unit [CR-101] enables creasing of up to four lines, which provides a high quality finish with less toner cracking for stand menus and sales promotional tools

Folding unit FD-503

Capable of double parallel and gate fold, as well as normal centre fold, tri-fold, Z fold. Furnished with features useful for producing DMs such as a wide variety of folding functions, and 2 & 3hole punching functions, as well as a sheet-inserter function capable of setting two different insert sheets.

Perfect binder PB-503

Perfectly binds up to 600 pages or up to 30mm thick. Cardstock up to 216 gsm can be used for the cover to realise high-quality bookbinding through advanced paper alignment. In addition, use of Multi-Folding Unit [FD-503] enables insertion of Z fold sheets while perfect binding is in process. This enables flexible bookbinding work owing to the ability to insert A3 size drawing sheets in booklets such as reports and manuals.

Finisher FS-532

The stapling finisher with staple cutter is capable of stapling up to 100*1 sheets. Three sub-options can be mounted to expand the system to enable saddle-stitching, post-insertion and punching, making it possible to perform multiple operations in a small space.

*1 Max. 50 sheets for A3

Saddle-stitcher SD-506

Capable of saddle-stitch bookbinding of up to 200 pages and furnished as standard with an fore-edge trimming function, multi centre folding and multi tri-folding functions.

Finisher FS-531/FS-612

The [FS-531] is capable of side stitching of a maximum of 50 sheets, in addition to a side-stitching function, [FS-612] is furnished with a saddle-stitching function and 2 types of folding functions for a maximum paper size of SRA3. If necessary, the system can be expanded to include functions for tasks such as punching and cover sheet insertion.

Large capacity stacker LS-506

Up to two units can be installed side-by-side for a total ejection capacity of 10,000 sheets. Finished documents can be taken out with the cart as they are for ease of transport to the next process. A sample ejection function allows quality checks to be performed during large volume printing.

High capacity paper handling

Maximum paper feeding capacity is increased to 15,390 sheets by connectable [PF-707m]*1 that is more than two times of C71hc (7,500 sheets). These improvements responds for demands of high volume jobs and short turnaround.

| Main Unit | PF-707m | PF-707m | PF-707m | |

| Upper tray | 500 sheets | 1,390 sheets | 1,390 sheets | 1,390 sheets |

|---|---|---|---|---|

| Middle tray | – | 1,390 sheets | 1,390 sheets | 1,390 sheets |

| Bottom tray | 1,000 sheets | 1,850 sheets | 1,850 sheets | 1,850 sheets |

| Total | 1,500 sheets | 4,630 sheets | 4,630 sheets | 4,630 sheets |

| Max. paper feed capacity: 15,390 sheets | ||||

Large capacity output tray OT-510

Output tray to accept maximum 4,200 sheets stack. Abundant paper stack capacity helps improve the efficiency in the off-line workflow where post-processing is a main work.

Excellent versatility

Expanded heavy paper compatibility to 350gsm

With the wide paper weight compatibility, print services including thick paper packages, tags, DMs, sales promotion tools are greatly expanded. The air suction paper feed mechanism incorporated in the feeder enables reliable feeding of thick paper that causes a high transport load. In addition, the enhanced paper catalogue function enables printing on a variety of paper types with ease.

Application for thick paper.

Package samples, name cards, DM, tag, simple photo book, stand menu, promotion materials, etc.

Envelope printing

Using an Envelope-dedicated Fusing Unit [EF-103], stable and high quality envelope printing is achieved, even when performing high speed printing. In addition, inexpensive, center-glued universal envelopes can be used thanks to less difference in glossiness on the overlapped area, contributing to a reduction of overall printing cost as well.

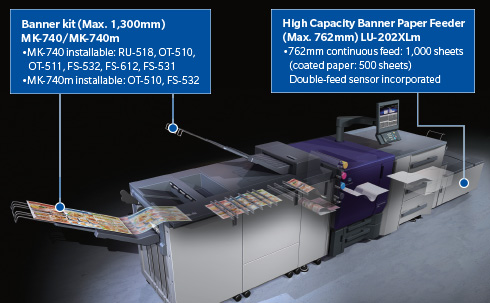

Enhanced banner printing (up to 1,300mm)and auto duplex banner printing

A4/Letter x 6-up is possible due to the banner printing capability of 840mm or longer, enabling production of A4 x four-fold catalogues and book jackets for A4 landscape booklets, etc. at high productivity that far exceeds large format inkjet printers. In addition, an auto duplex banner printing function is available that can accept a maximum of 762mm long, allowing efficient print work for the production of A4/letter size tri-fold menus, pamphlets and catalogues. These superior features help differentiate print services from others.

Newly adopted options for effective banner printing

The newly-adopted LU-202XLm that can continuously feed max. 1,000 sheets of 762mm banner format enables efficient banner printing including book covers, three-fold menus, etc. In addition, connecting the optional “MK-740m” enhances operability during high volume output.

Technologies to support the versatility & high quality

Technologies to support the versatility & high quality

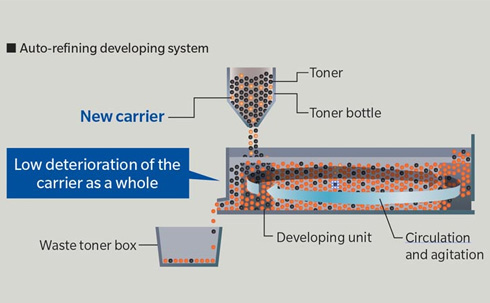

Stabilised developer activity reduces image degradation

A new carrier is supplied together with the toner to refresh the carrier in the developer, stabilising the developer condition to maintain high image quality throughout the system lifetime. This auto-refining system is available for all four colours, realising highly stable and quality image reproduction in full colour printing. The longer developer life also minimises downtime.

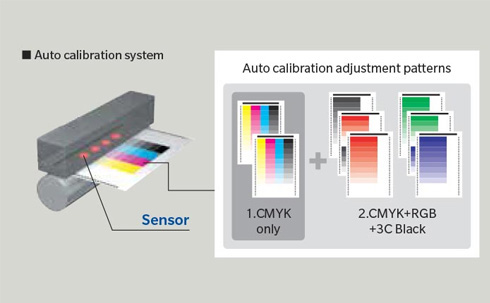

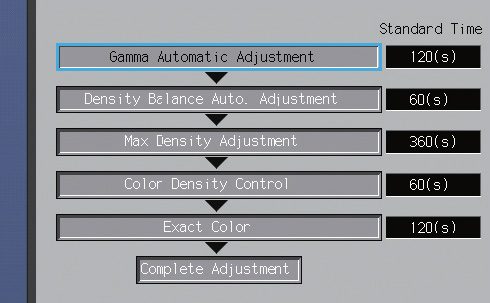

Auto-calibration system

An output paper density adjustment function to correct gradation density to match output paper characteristics is equipped. Adjustments are performed using the paper actually used to enable accurate gradation adjustment matched to the paper characteristics. Fifteen different correction values for different paper types or screens can be set. A mode that measures secondary colour (RGB) in addition to CMYK as target colours has been added to further enhance accuracy.

Major functions of RU-518

Hybrid decurl system

The hybrid decurling mechanism using two functions can be configured by adding a Humidifier Kit [HM-103] to the Relay Unit [RU-518] on which a mechanical decurler is already mounted in standard. The humidifying function cools down the sheet that was heated in the fusing unit, and provides moisture lost from the sheet back to reduce the stiffness for

effective curl adjustment. This not only corrects the curl but also provide an expectation for removal of static electricity, which substantially contributes to the work efficiency in off-line post processing. The replenishing water for the humidifier is easily supplied from upper part of the RU-518 during printing.

Real time curl adjustment

Real-time curl correction is made possible by adding a Relay Unit [RU-518] to the system. Paper curl can be adjusted very precisely in 20 steps. This provides flat surface prints without interrupting print operation, and reduces the workload and waste in post-processing.

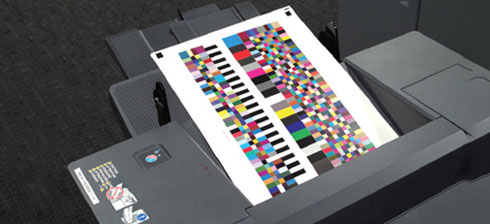

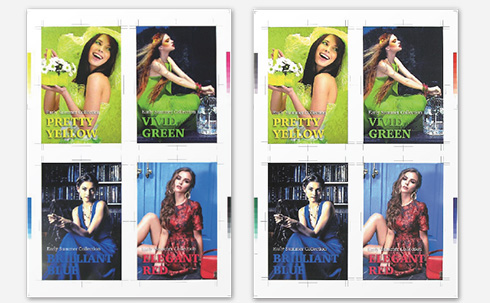

Automated adjustments to maintain the highest quality

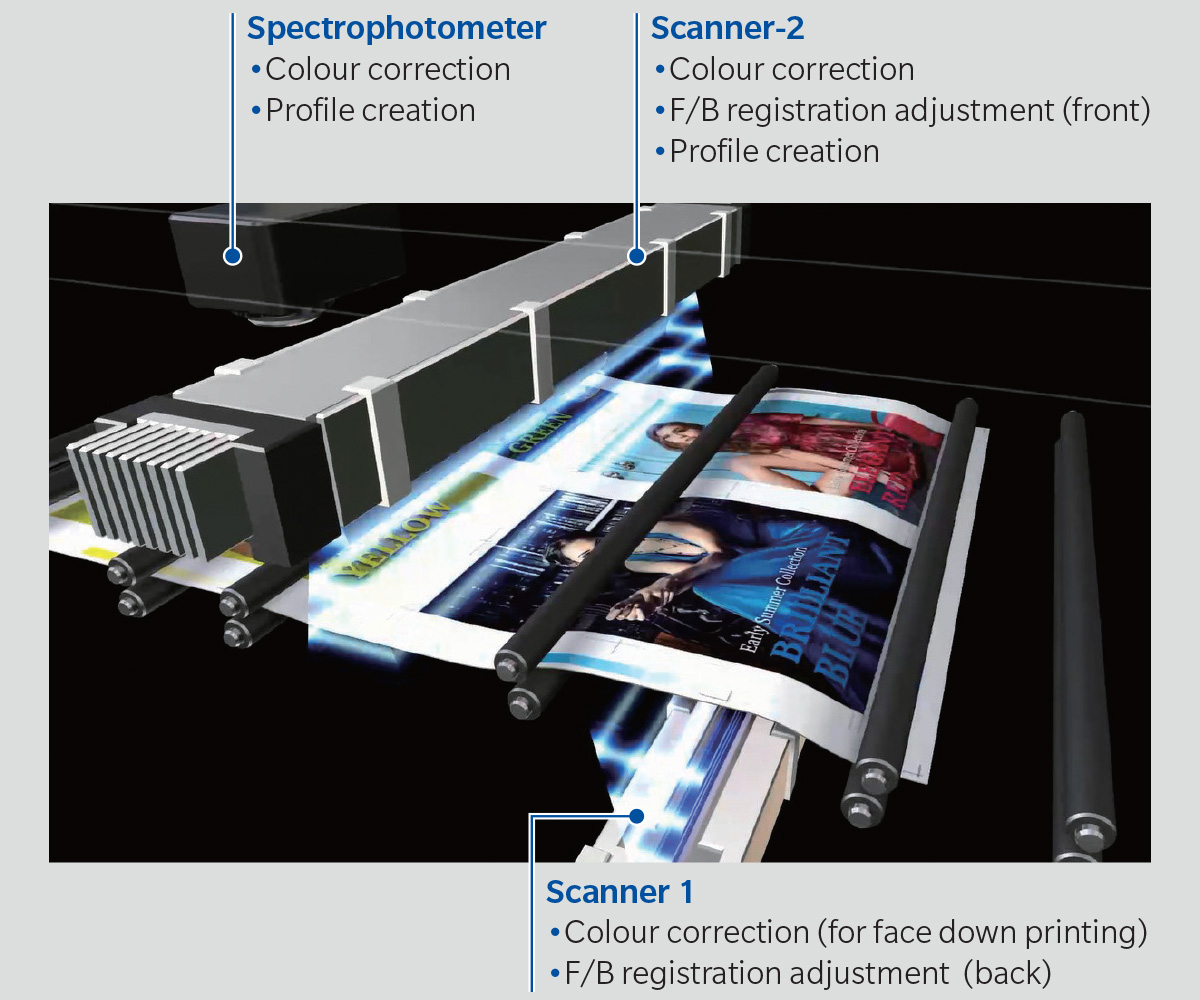

Using the Intelligent Quality Optimiser [IQ-501] (option), it is now possible to automatically perform colour / front-to-back registration adjustments, thus considerably reducing the time required for adjustments and contributing to higher operation rate for production. Measurements and inputs performed manually in the past are no longer necessary. Less human intervention leading to fewer human errors enables the consistent provision of high-quality print products. In addition, colour reproduction and front-to-back registration are monitored and controlled in real time during printing operation. Consistent realisation of high-quality print contributes not only to the reduction of print waste, thus reducing

Hybrid colour measurement

The IQ-501 is furnished with two scanners, enabling measurements for front-to-back registration in one pass. Measured data is used for various auto adjustments and converted into density values for real-time adjustments. Konica Minolta’s spectrophotometer, which has won acclaim for its measuring accuracy is furnished. Hybrid colour measurement combined with scanners enables colour balance and printer profile adjustments with higher accuracy and in a shorter time.

Intelligent Quality Optimiser IQ-501

| Option required | VI-511 (Image Processing Board) |

| Paper size | 95 x 139mm to 331 x 488mm |

| Paper weight | 62 to 350gsm |

| Reading width | Max. 350mm |

| Power source | 100 to 240VAC, 50/60Hz |

| Power consumption | Max. 700W (Inc. Connection Option) |

| Dimension (W x D x H) | 663 x 696 x 1,020mm |

| Weight | Approx. 184kg |

Major functions of IQ-501

Auto adjustment functions before production.

Real time monitoring & correction during printing

Auto printer profile creation

Real-time colour & registration monitoring and correction

Colour tone and front-to-back registration are monitored and automatically corrected in real time without degrading productivity. As a result, colour fluctuations and registration misalignment are controlled to a minimum, which helps provide high quality print products in a stable manner. Stable results are ensured in printing of company logos for which the colour stability is essential, and cards, page numbers of booklet and ruled lines for which accurate positioning is essential. In addition, print waste caused by instable colour and registration is minimised, contributing not only to cost reduction but also to improve customer trust.

Technologies to support the consistent quality

Technologies to support the consistent quality

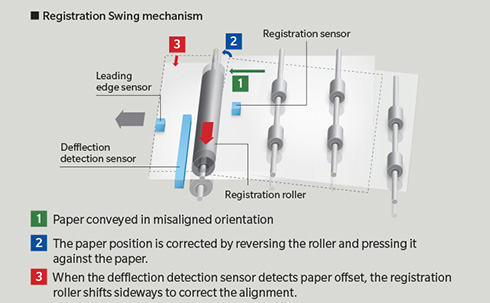

High precision registration mechanism

A registration swing mechanism capable of highly accurate detection of paper misalignment and skew is furnished, realising a professional finish for duplex printing that needs to be accurate for use in additional printing and for trimming/bookbinding. The mechanism also automatically corrects paper-feeding misalignment in the main unit tray, contributing to both improved quality and higher productivity. Paper conveyed in misaligned orientation is pressed against the registration roller to correct the misalignment, while the registration swing mechanism moves shifted paper into the correct position.

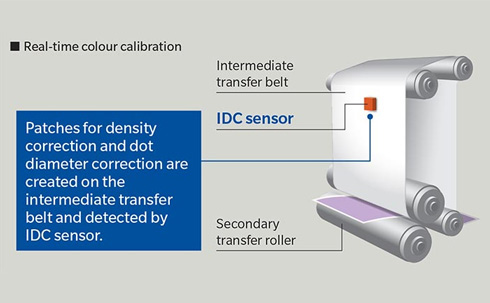

Real-time image optimisation with IDC sensor

This function controls image stability in short intervals during continuous printing by detecting density correction patches and dot diameter correction patches created on the intermediate transfer belt furnished with an IDC sensor, delivering stable high quality for a wide range of densities through 2 types of density calibration. Reducing print waste relating to colour reproduction helps not only to reduce production costs but also to enhance customer trust.

Usability

Konica Minolta Image Controller [IC-605]

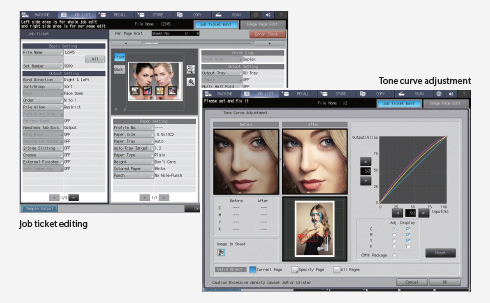

Job control/editing is enabled also from the main unit control panel

Allows job management including job ticketing and pagination with intuitive operation. Tone curves can be also adjusted in a similar manner to that of Color Centro. In addition, connecting a USB mouse provides an operational environment similar to a PC.

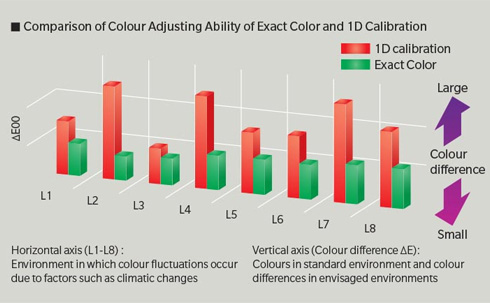

Color Centro (Colour Management Utility)

Equipped with Exact Color, which performs high-precision 3D calibration, realising a major improvement in colour adjustment capability over conventional 1D calibration. Work, editing, setting and other tasks relating to colours matched to the main body can be performed, such as colour adjustment, creation of colour profiles and simulations. These functions are also available for RIP files.

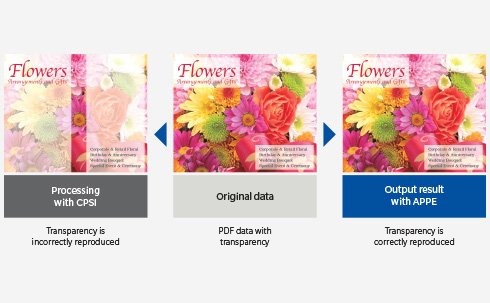

Equipped with APPE 4.6 (optional)

Equipped with Adobe’s APPE 4.6 (Adobe PDF Print Engine 4.6), which directly processes PDF files without having to access a printer driver for appropriate transparent effects.

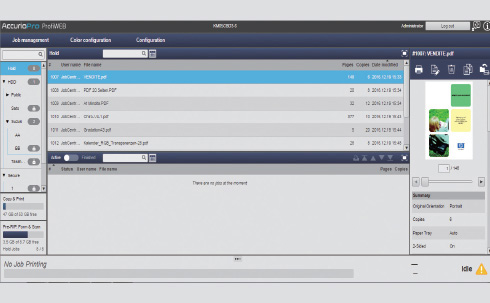

AccurioPro Print Manager

Using the web browser, the job management through sophisticated interface is made available. An easy-to-use interface having a high degree of affinity with the main body panel and printer driver supports more efficient operation. In addition, tone curve adjustment function for each job (or each page) is available.

JDF compatibility

Thanks to compatibility with JDF, a standard format for the display use familiar CTP workflow RIPs such as APOGEE, EQUIOS and Prinergy*1 for a hybrid workflow with a seamlessly connected offset printer. Digital printing thus becomes an offset printing option that enables more flexible handling.

*1 Google Drive, Gmail, Evernote

*2 SharePoint Server 2007/2010/2013/2016

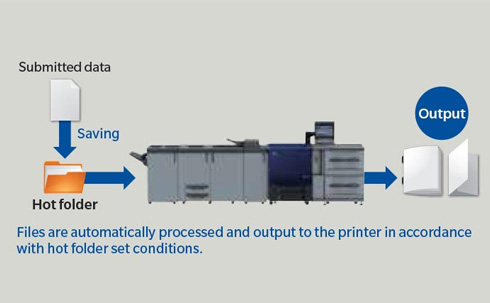

AccurioPro HotFolder

AccurioPress is equipped with a hot-folder utility that further enhances work efficiency and is ideal for automatic processing of items such as documents that need to be printed regularly and documents that can only be handled by specific printing processing. The hot-folder utility contributes to reduction of manpower required for job registration as well as of processes need to be performded by the operator..

Command WorkStation

Efficiently manages jobs from a PC on the two screens of Job Center and Device Center.

Fiery Print Controller [IC-313/IC-417]

High speed processing & high quality

Realises both RIPping at 1200dpi × 8bit and high speed processing.With a wide range of colour profiles, flexible colour management is made possible.

Colour management

IC-313/417 performs colour management for each CMYK, RGB and spot colour space irrespective of the application or file format, making it ideal for colour management matched to purposes such as proofing and production of final deliverables.

Equipped with APPE 4.4

Equipped with a new APPE 4.4 (Adobe PDF Print Engine 4.4), which supports transparent effect processing of PDF files as standard*1.

Improves the productivity / cost by optimising the workflow

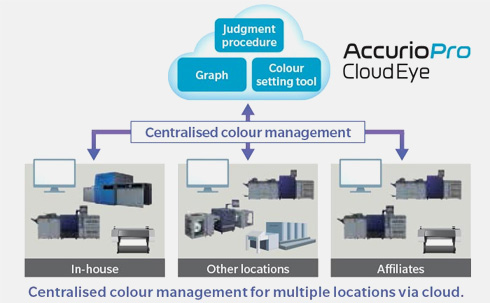

AccurioPro Cloud Eye

Konica Minolta’s cloud colour management system enables centralised colour management of printers at multiple locations (in-house offices and factories, affiliates’ facilities, etc.) via cloud. The colour reproduction of all connected printers, of wide-ranging models, is accurately monitored without requiring special skills.

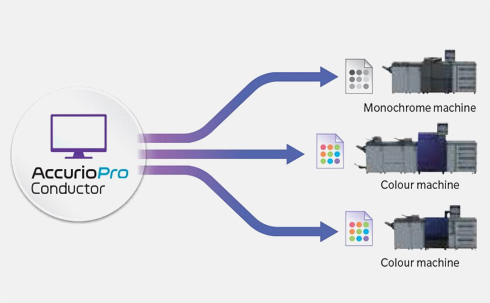

AccurioPro Conductor

Unified management of multiple printers together with automated operation of various functions helps substantially improve work efficiency, allowing seamless processing of print jobs that are different in profile and purpose. In addition, a function is also available to automatically print only the monochrome pages of the document on a low cost monochrome printer, contributing to a reduction in overall print cost.

OpenAPI/IWS supported

Supports bizhub Connector that enables linkage to office machines. Adding and registering the application in the main unit allows the operation panel on the main unit to connect to various cloud-based services*1 and SharePoint Server*2, realising a linkage with external services including upload of scanned data and direct print. In addition, incorporated OpenAPI ver. 4.7 allows utilisation of solution applications including authentication, charging and ubiquitous printing, etc.

Ecological Design

In addition to the energy-saving performance targeted by Simitri HDE, an optimised fusing process reduces fusing temperatures to reduce energy use.

Using a high combination of recycled resins and bioplastics, resources are effectively used and environmentally considerate materials are actively employed. A lead-free shaft is also

adopted to protect the environment as well as the user’s health.

| C83hc | C73hc | ||

| Type | Console type | ||

| Colour Support | Full colour(Wide colour gamut witd high chroma toner) | ||

| Output Resolution | 3,600 dpi(Equivalent)x 1,200 dpi | ||

| Gradation | 8-bit / 256 gradation | ||

| CPU | Core i5 4570S 2.9 GHz | ||

| System Memory | 4GB | ||

| Paper weight | Standard mode | 62 gsm to 350 gsm (Auto duplex),(81 gsm to 350 gsm : Coated paper) | |

| Banner printing mode | 128 gsm to 256 gsm | ||

| Standard trays | 62 gsm to 216 gsm,(62 gsm to 256 gsm : A4 or larger size) | ||

| Optional trays | 62 gsm to 350 gsm (PF-707m,MB-506) 62 gsm to 300 gsm (MB-508, PF-602m, LU-202m, LU-202XL, LU-202XLm) |

||

| Paper Size | Standard mode | SRA3, A3, B4, SRA4, A4, SRA4S, A4S, B5S, A5S, 12” x 18”, 11” x 17”, 81/2” x 11” Min. 139.7 mm x 182 mm to Max. 330.2 mm x 487.7 mm |

|

| Banner printing mode | Max. 330.2 mm x 1,300 mm (Max. 330.2 mm x 762 mm : Auto duplex) | ||

| Optional trays | 100 mm x 148 mm to 330.2 mm x 487.7 mm (MB-506/MB-508), to 330.2 mm x 1,300 mm (witd MK-740) 100 mm x 139.7 mm*1 to 330.2 mm x 487.7 mm (PF-707m) 100 mm x 148 mm*1 to 330.2 mm x 487.7 mm (PF-602m, LU-202m) 100 mm x 148 mm*1 to 330.2 mm x 750 mm (LU-202XL), to 330.2 mm x 762 mm (LU-202XLm) |

||

| Max. printing area | 323 mm x 480 mm, (323 mm x 1,295 mm : Banner paper) | ||

| Image loss | Top edge: 4.0 mm or less, Bottom edge: 3.0 mm or less, Right/Left edge: 3.0 mm or less | ||

| Warm-up time | 390 sec. or less (At room temperature) | ||

| Print speed*2 | A4 (Landscape) | 81 ppm (Full colour/Monochrome) | 71 ppm |

| A3 | 45 ppm (Full colour/Monochrome) | 39 ppm | |

| Paper feeding capacity (80 gsm) | 1,500 sheets (Standard tray), Max. 15,390 sheets (Standard tray + PF-707m x 3 units) | ||

| Paper output capacity (80 gsm) | 150 sheets (witd optional output tray OT-511), Max. 10,000 sheets (LS-506 x 2 units) | ||

| Power source | Metric: AC 220V to 240V, 25A, 50Hz/60Hz | ||

| Power consumption (Main unit only) | Metric: Max. 6,000W | ||

| Dimension | 800 mm x 903 mm x 1,041 mm (Main body only) | ||

| Space required | 631 mm or more for front (for sliding out ADU unit), 200 mm or more from the rear duct, 100 mm or more for both sides | ||

| Weight | Approx. 313 kg | ||

*1: with small size guide.

*2: Print speed may vary depend on paper type.

| Type | Embedded (AIO to the engine, option) |

| CPU | Intel Core i5 4570S 2.9GHz (Main unit specification) |

| Memory | 4GB (Standard of the main unit) +8GB (IC-605B), +4GB (UK-104)Max. 16GB |

| HDD | 1TB x3 (+500GB with UK-103) |

| Network | 10/100/1000 Base-T |

| Power source | Supplied from the main unit |

| Resolution | 600x600dpi, 1,200×1,200dpi |

| Page description language | Adobe PostScript3 (CPSI3020), PDF direct print (PDF ver. 1.7), APPE (Ver. 4.6) (UK-104 and UK-218 are required), PDF/VT (Ver. 2.0) (UK-104 and UK-218 are required), TIFF direct print (TIFF Ver. 6 compliance), PPML (ver. 2.2), PCL-5c compatible, PCL XL (PCL6 Ver. 3) compatible |

| Protocol (Printing method) | TCP/IP, NetBEUI, IPP, WSD, SMB, Bonjour |

| OS | Windows 7 / 8.1 /10 Windows Server 2008 / 2008R2 / 2012 / 2012R2 / 2016<>/br Mac OS 10.9-10.13 |

| System | Linux |

| Main fonts | Adobe 136 fonts, PCL 80 fonts |

| Driver | PS Plug-in, PPD |

| Scanner resolution | 200 / 300 / 400 / 600 dpi |

| Data Format | PDF, TIFF, JPEG, XPS, Encrypted PDF, PDF/A-1a,1b |

| Option | UK-218 (APPE kit), UK-104 (Extension memory, HDD) |

| Type | Server type |

| CPU | Intel Core i5 4570 2.9GHz |

| Memory | 4GB |

| HDD | 1TB |

| Network | 10/100/1000 Base-T |

| Power source | Max. 350W |

| Resolution | 600x600dpi, 1,200×1,200dpi |

| Page description language | Adobe PostScript3 (CPSI 3020), PDF Ver.1.7, APPE (Ver. 4.4), FreeForm (Ver. 2.1), PPML (Ver. 2.2), PDF/VT (Ver. 2.0), CreoVPS, PCL (5, 6) emulation |

| Protocol (Printing method) | TCP/IP, SMB, LPR, Bonjour, SNMP, IPP, FTP |

| OS | Windows 7 / 8.1 /10 Windows Server 2008 / 2008R2 / 2012 / 2012R2 / 2016 Mac OS 10.9-10.13 |

| System | Windows 10 |

| Main fonts | 138 fonts |

| Driver | PostScript 3 |

| Scanner resolution | 200/300/400/600 dpi |

| Data Format | PDF, TIFF, JPEG |

| Option | Fiery Impose-Compose, ES2000/EFI Color Profiler Suite, GA Package Premium Edition, Job Master |

| Type | Embedded (AIO to the engine, option) |

| CPU | Intel G4400, 3.3 GHz |

| Memory | 4GB |

| HDD | 500GB |

| Network | 10/100/1000 Base-T |

| Power source | Max. 150W |

| Resolution | 600x600dpi, 1,200×1,200dpi |

| Page description language | Adobe PostScript3 (CPSI 3020), PDF Ver.1.7, FreeForm (Ver. 2.1), PCL (5,6) emulation |

| Protocol (Printing method) | TCP/IP, SMB, LPR, Bonjour, SNMP, IPP, FTP |

| OS | Windows 7 / 8.1 /10 Windows Server 2008 / 2008R2 / 2012 / 2012R2 / 2016<> Mac OS 10.9-10.13 |

| System | Linux |

| Main fonts | 138 fonts |

| Driver | PostScript 3 |

| Scanner resolution | 200/300/400/600 dpi |

| Data Format | PDF, TIFF, JPEG |

| Option | Fiery Impose-Compose, Hot Folder, Auto Trapping, ES2000/EFI Color Profiler Suite, Embedded Productivity Package, Job Master |