The professional handling capabilities of the AccurioPress C6100/C6085 help professional printing companies meet tight deadlines with ease. Whether handling thin or thick paper, it maintains 100% productivity.

Key features

High productivity

Whether handling thin or thick paper, it maintains 100% productivity

Media handling

Upto 400 GSM.

Diverse output expands printing service possibilities

Upto 1300mm and auto duplex upto 762mm

High productivity

High productivity and reliability for fast turnaround

The professional handling capabilities of the AccurioPress C6100 help professional printing companies meet tight deadlines with ease. Whether handling thin or thick paper, it maintains 100% productivity.

When productivity and short turnaround are critical

Productive printing irrespective of paper thickness

High-speed 100ppm output

Whether printing paper of 52 or 400gsm thickness, the large-diameter upper fusing system and Simitri HDE toner synergise to output 100 sheets per minute*1. The large contact area of the fusing belt, optimised for rapid and uniform thermal conduction, contributes to outstanding toner fusion and high productivity.

*1:For A4 horizontal on C6100 (85 sheets per minute on C6085)

Fast and easy paper settings

Enhanced paper menu and search functions

Default settings are provided for every type of paper and additional settings can be registered to meet every need. Simple settings and user-friendly search functions contribute to easy setup and high productivity.

Easy large-volume printing

Large-volume paper feed and output system

The system can be expanded to feed a maximum 13,890 sheets and output a maximum 10,000 sheets using 9 varieties of paper. Paper replenishment and removal, for both paper feeding and output, are possible during printing to simplify large-volume processing tasks.

Highly efficient scanning

High-speed duplex scanner PF-711*optional

The high-speed duplex scanner is ideal for law offices, educational establishments and others that need to scan and store large volumes of documents as data. It reads 75 colour or 80 monochrome pages per minute*1 with high reliability thanks to a built-in high-speed double-feed detector

*1: A4, 300dpi (duplex scanning of 150 colour pages or 160 monochrome pages.

Paper position correction for every thickness

Rotary-type high-precision registration

An advanced registration unit improves front-to-back registration for duplex printing. Its paper angle detection sensor detects angles of the leading edge of the paper immediately after passing the loop rollers. The rear and front loop rollers can be driven independently to change speed and correct the angle. The result is improved front-to-back registration of a wide range of paper types and high-quality finishing of items such as booklets with photo spreads.

Curl correction and static elimination

Hybrid decurler*optional

Optimum paper curling correction can be realised by combining relay unit RU-511/518*1, which employs a standard mechanical decurler ideal for coated sheets, with optional humidifier kit HM-101 for uncoated sheets. The degree of decurling can be adjusted manually and responds flexibly to changes in conditions.

*1:RU-518 is scheduled for release in 2017.

Mechanical decurler

Relay unit RU-511/518 feeds paper through a zigzag passage to reduce paper curls. Decurling strength can be adjusted in five steps for optimal curl removal from thin and thick paper.

Humidifier type decurler*2

In addition to removing curls from uncoated paper by humidification, the Humidifier Type Decurler helps prevent paper sticking by cooling and minimising static electricity.

*2:With optional relay unit RU-511/RU-518 and humidifier kit HM-101 installed.

Centralised management of multiple machines

AccurioPro Conductor

AccurioPro Conductor is a workflow integration system for managing Konica Minolta’s AccurioPro printing solutions. It improves work efficiency by centrally managing multiple printers, automating various operations, and enabling the seamless implementation of diverse printing jobs of different specifications and requirements. Cost-saving measures are also included, such as a feature that automatically prints only the monochrome pages of a document using a low-cost monochrome machine.

Flexibility

Diverse output expands printing service possibilities

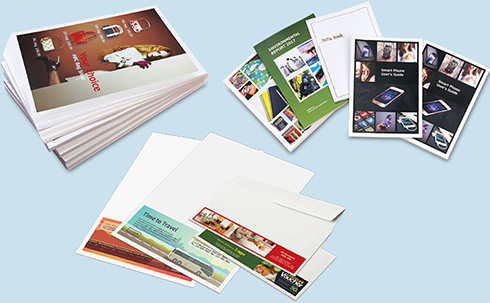

AccurioPress C6100/C6085 expands business potential by flexibly supporting 400gsm thick paper, banner printing (max. 1,300mm long), envelope printing and more at low cost.

Thick paper printing

Banner printing

Envelope printing

Thick paper compatibility

Up to 400gsm thick

Printing is possible on 400gsm thick paper even during automatic duplexing — with solid stability and no loss of productivity. This capability expands the range of potential applications to include thick-paper tags, stand-up menus, sales promotion tools and more.

Reliable paper conveyance

Fusing belt steering mechanism

Konica Minolta’s original fusing system improves media compatibility. An advanced inlet roller and fusing belt steering mechanism in the air blow fusing separation mechanism enhance conveyance reliability for all paper thicknesses to meet the needs of on-demand high-mix printing.

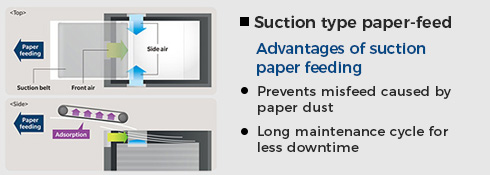

Reliable feeding of all media

Air-suction paper-feed system *optional

Feed unit PF-707m/PF-711 features a suction-belt paper feed mechanism. The air-assist mechanism blows air from the front as well as the sides to separate sheets and realise adsorption of the paper to the suction belt for conveyance. Air control is adjusted for each paper type and an improved adsorption area during belt paper feeding ensures stable feeding of thick and coated paper.

Diverse printing capabilities

Envelope and banner printing functions

A fusing unit dedicated to envelope printing ensures stable, high-quality printing on general-purpose envelopes with minimal folding creases or differences in adhesive strip gloss. Printing of banners up to 1,300mm long, with auto duplexing of banners up to 762mm long, is also top-of-class. The mounted LU-202XLm enables continuous paper feeding of up to 1,000 sheets (up to 762mm) and optional accessories can be added to improve embossed paper printing quality.

Stable, high-quality banner paper output

Banner output-compatible relay unit RU-518

The RU-518 relay unit features a banner ejection function and is capable of outputting banners up to 1,300m long. It can be mounted with a hybrid decurling unit to handle not only decurling, but also functions such as paper cooling and static electricity prevention.

Banners up to 1,300mm long

Banner bypass unit MB-508 Banner kit MK-740

The MB-508 banner bypass unit can be mounted on PF-711 and PF-707m paper feeding units. Banner kit MK-740 enables paper feeding of banners up to 1,300mm long.

Consistent high-quality envelope printing

Envelope printing-dedicated fusing unit EF-104

Designed especially for envelope printing, the EF-104 fusing unit realises fast, high-quality envelope printing at low cost.

Large-volume paper feeding of banners up to 762mm long

Banner compatible high-volume paper feed unit LU-202XLm

The LU-202XLm paper feed unit can continuously feed up to 1,000 banner sheets (maximum 80gsm thickness and 762mm length).

High quality

Consistent image output of the highest quality

Extremely high image quality can be consistently maintained by taking advantage of abundant screens, character quality adjustment functions, and S.E.A.D. V technology utilising the latest Konica Minolta imaging process advances.

When character quality is critical

When image quality is critical

Cutting-edge image processing technology

S.E.A.D.V

Konica Minolta’s unique Screen-Enhancing Active Digital system combines highly accurate exposure controls, precision pixel placement and advanced screening to achieve high quality and resolution. It also allows flexible processing and image smoothing control to match varying needs.

High quality and energy savings

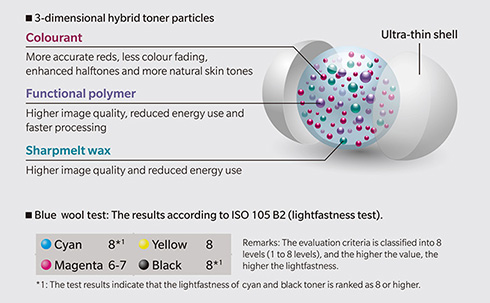

Simitri HDE toner

This next-generation toner with 3-dimensional polymer structure is highly compatible with all types of media, expands the colour gamut for superior image accuracy and produces more natural skin tones. It also requires less heat for fusing, which helps reduce power consumption.

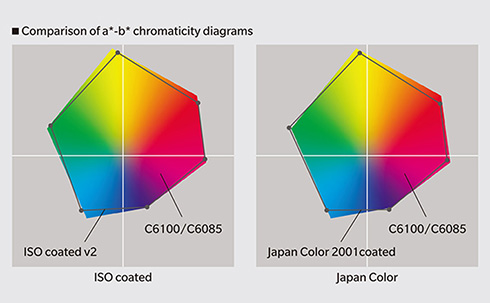

Wide colour range

ISO coated and Japan Color coated

TAccurioPress colour expression rivals offset machines thanks to Simitri HDE toner that covers ISO coated and Japan Color coated gamuts while requiring minimal toner.

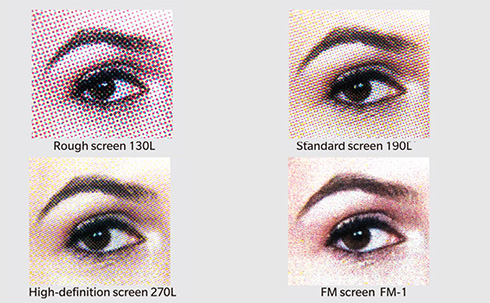

Selectable to match applications

12 high image quality screens

Six dot screens, three line screens and three FM (frequency modulation) screens are provided so the right screen can be selected for each material and purpose.

Near offset printing character quality

Character line thinning and edge enhancement

Character quality and legibility are top class. A line-thinning function helps prevent thickening of characters and blurring of white characters. A contour enhancement function reduces roughness on dot-background character edges and characters of intermediate colours. Both features can be adjusted in five steps for fine-tuning.

Stable hue control without lowering productivity

Real-time calibration

An advanced IDC sensor realises highly stable, high-precision automatic colour calibration. Printed materials of unerringly consistent high quality can be produced with no loss of productivity even during high-volume printing.

High registration accuracy

Skew and image rotation correction

Image rotation and skew correction values can be input to adjust front-to-back registration for items such as business cards, shop cards and tickets that require a high level of front-to-back registration accuracy.

Suppression of temperature fluctuations

Built-in cooling fan

A cooling fan circulates air in the main unit to maintain a fixed temperature and help realise more consistent colour.

High-precision calibration

Exact Color

High-precision 3D calibration realises more accurate colour adjustment than conventional 1D calibration. Colour profile creation, simulations and other colour related tasks can also be performed accurately even for rasterised images.

Automation

Auto colour management and front-to-back registration (optional)

Optional Intelligent quality optimiser IQ-501 continuously monitors and adjusts colour and front-to-back registration during printing. So materials are produced with consistent high quality, less manual adjustment and no need for special skills.

When registration accuracy is critical

When colour reproduction is critical

Greater output and shorter turnaround

Auto colour and front-to-back adjustment before printing

Automation of density adjustment, colour management and front-to-back registration reduces time previously spent making adjustments. Since tasks such as manual measurements and input of numerical values are no longer necessary, there are fewer measurement and input errors. Colour profiles can also be created automatically to achieve highly accurate colour matching in less time.

Stable quality made fast and easyOne-step auto adjustment

Common settings such as maximum density, density balance and gamma adjustment are automatically adjusted in a single step to save time and raise accuracy.

Real-time gradation and front-to-back registration adjustment

Gradation and front-to-back registration are continuously monitored and corrected in real time with no loss in productivity. This feature improves image quality by minimising colour fluctuations, registration misalignment and other errors during printing. It also lowers costs by reducing paper waste.

Paper sizes compatible with real-time gradation and front-to-back registration adjustment

| Standard sizes | SRA3, SRA4 or paper with margins in the sub-scanning direction |

|---|---|

| Nonstandard sizes | 225mm or more in the sub-scanning direction |

Centralised colour management for multiple locations via cloud

AccurioPro Cloud Eye

Konica Minolta’s cloud colour management system enables centralised colour management of printers at multiple locations (in-house offices and factories, affiliates’ facilities, etc.) via cloud. The colour reproduction of all connected printers, of wide-ranging models, is accurately monitored in real-time without requiring special skills.

Paper sizes compatible with real-time gradation and front-to-back registration adjustment.

| Problems with separate colour management in each location | |

| Lack of consistency due to differences in judgment criteria, setting methods, etc. | 2More total time spent communicating, managing and checking. |

| Centralised colour management for multiple locations via cloud | |

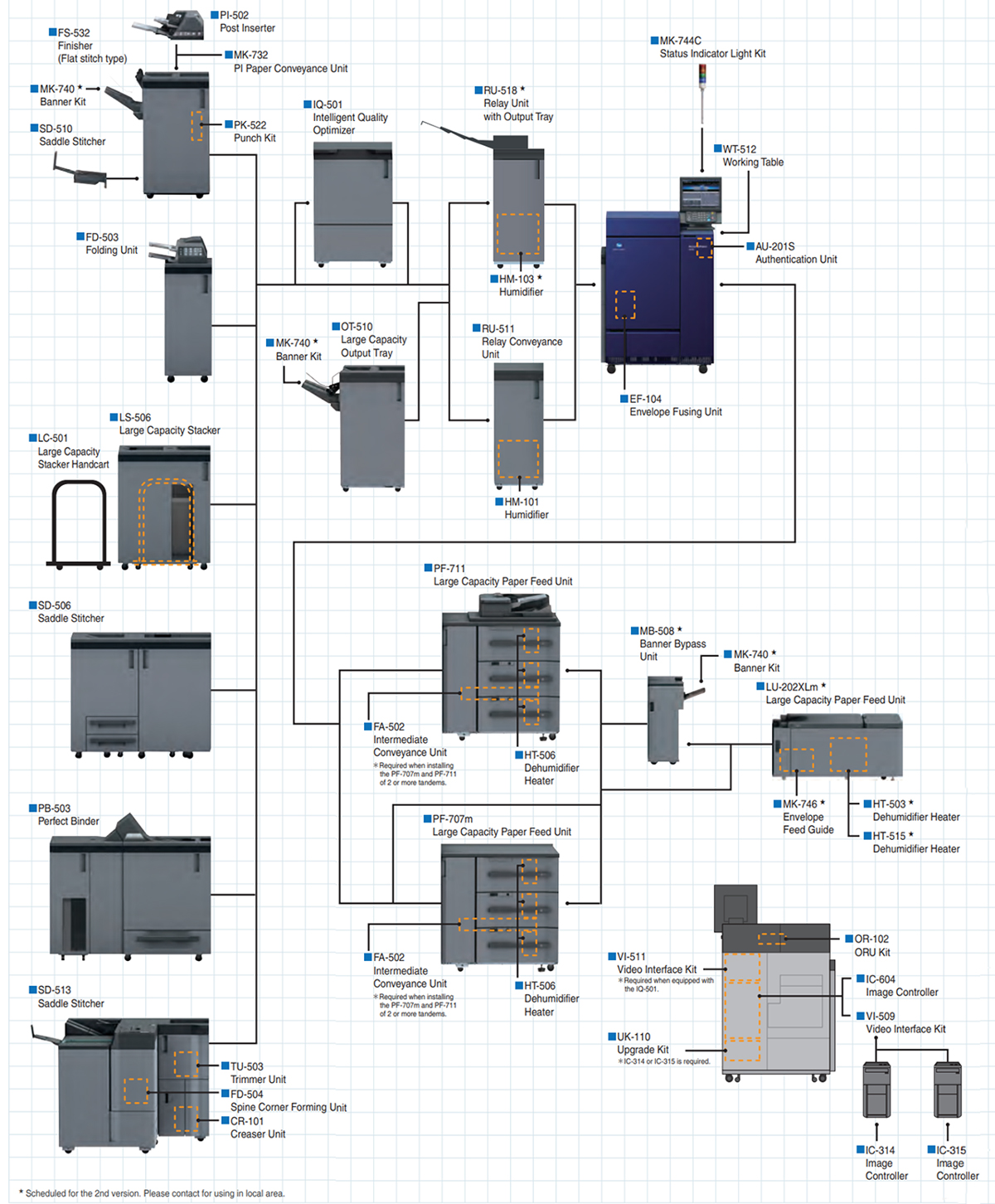

Inline finishing

A diverse inline finisher lineup for added value

A wide range of inline finishing options are available that boast top-of-class professional specifications. They efficiently meet the needs of diverse output formats to enable services that can differentiate companies from the competition.

Thick perfect bookbinding

Flat-back full-bleed saddle-stitched bookbinding

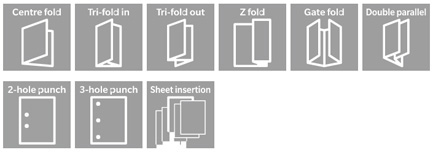

Wide range of folding functions

Sophisticated saddle-stitched bookbinding

T-shape saddle stitcher SD-513

This unit provides all the refined saddle-stitching capabilities of an offset printing bookbinder when combined with Square Corner Forming unit FD-504, creaser unit CR-101 and trimmer unit TU-503.

*1: With FD-504 mounted *2: With CR-101 mounted *3: With TU-503 mounted.

Spine Corner Forming unit FD-504

This unit creates a spine corner for saddle-stitched booklets to reduce booklet swelling and allows adjustment of flat back strength.

Creaser unit CR-101

The creaser unit applies creases to folding lines to prevent the toner from cracking for a neater finish.

Trimmer unit TU-503

This unit trims both upper and lower edges and can produce full bleed booklets when used in combination with the standard fore edge trimming unit.

Space-saving all-in-one finisher

Staple finisher FS-532

The staple finisher is capable of stapling up to 100 sheets*1 and cutting the excess length from staple legs. With the saddle-stitcher option mounted, tasks such as multi tri-folding and centre folding can be performed in addition to saddle stitching. High paper alignment and a revised paper-feed path ensure a neat finish even for large numbers of stitched sheets. The unit can also be expanded with a punch and post inserter*2.

*1:Stapling for up to 50 sheets of A3 paper.

*2:Mount kit MK-732 required for installation.

Note: Some combinations of options are not compatible

*3: With SD-510 mounted

*4: With PK-522 mounted

*5: With PI-502 mounted

Perfect binding of up to 600 pages

Perfect binder PB-503

This unit provides a top-of-class perfect binding finish for up to 300 sheets/600 pages of 80gsm thickness up to a total binding thickness of 30mm. Paper up to 216gsm thick can be used for the cover and both printing and gluing can be performed inline. Sophisticated sheet alignment technology realises a neat finish even without three-edge trimming. Completed bound books are stacked automatically on a provided stacking cart.

For small-lot manuals, catalogues, etc.

Saddle stitcher SD-506

This saddle stitcher can create booklets of up to 50 sheets/200 pages (80gsm). A set-on-saddle mechanism allows stiff, accurate folding that decreases sheet misalignment during binding. Double-parallel and tri-fold functions, as well as a fore-edge cutting function that provides a neat finish, are standard equipped for efficient post-processing.

Ample capacity for high work efficiency

Large-capacity stacker LS-506

Up to two stacker units that accommodate 5,000 sheets each can be installed side-by-side for a total 10,000-sheet capacity. Finished documents can be removed via cart for easy transport to the next process. A sample ejection function allows quality checks during high-volume printing.

Double-parallel folding, gate folding and more

Multi-folding unit FD-503

The FD-503 is a multi-function multi-folding unit capable of double-parallel folding, gate folding, centre folding, tri-folding and other tasks. It can quickly handle diverse jobs such as DM production. The unit is also furnished with 2 and 3-hole punching functions and a sheet-insert function. When combined with the PB-503, it can insert Z-folded pages in perfect bound books.

Low-cost high-capacity output tray

High-capacity output tray OT-510

The capacity of this low-cost output tray has been increased from 500 sheets to 4,200 sheets. It’s a highly cost-effective initial investment for users with standalone post-processing equipment.

Usability

Streamlined operation improves the workflow

User-friendly operation increases output efficiency, especially when the optional print controller IC-604 is employed to optimise the workflow for even higher output and improved colour management.

High-precision automatic scanning spectrophotometer

Super high-speed spot measurement reduces colour adjustment workflow time.

15-inch main unit operation panel

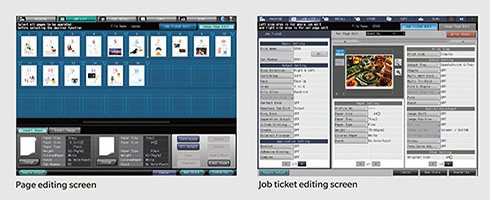

Job and page editing can be handled from the large, easy-to-use operation panel, which is mouse-compatible.

Improved data handling efficiency

Job control/editing with the main body panel

Management of jobs including job ticketing and pagination is intuitive on the user-friendly screen. Tone curves can be adjusted in a similar manner to that of Color Centro and a USB mouse can be connected for PC-like operation.

Colour management utility

Color Centro

Color Centro includes Exact Color colour management software that enables high-precision 3D colour calibration superior to that of conventional 1D calibration. Editing can be performed and settings can be made for colour verification, G7 calibration, ICC profile creation, etc. without using a PC.

High-precision spectral densitometer

Konica Minolta’s high-precision spectral densitometer FD-5BT*1 can be used to perform tasks such as ICC profile creation and calibration.

It can also be used as a standalone densitometer with a display in the CTP room. Auto scan spectral densitometer FD-9*1, a higher end product, can also be used with the C6100 Series.

*1:Optional

State-of-the-art printing-reproduction function

Standard APPE 4.2

APPE 4.2 (Adobe PDF Print Engine 4.2) bypasses the printer driver to directly process PDF files for appropriate reproduction of transparency.

Job management utility

Job Centro 2.0

Job management from PCs is simplified by an outstanding interface with elements such as indicators and thumbnails that enhance operating ease and efficiency.

Seamless offset printing connectivity

JDF compatibility

Thanks to compatibility with JDF, a standard format for the display and transfer of jobs between printing processes, the operator can use familiar CTP workflow RIPs such as APOGEE, EQUIOS and Prinergy*1 for a hybrid workflow with a seamlessly connected offset printer. Digital printing thus becomes an offset printing option that enables more flexible handling.

*1:”APOGEE” is a product of Agfa-Gevaert N.V. “EQUIOS” is a product of SCREEN Graphic and Precision Solutions Co., Ltd. “Prinergy” is a product of Eastman Kodak Company

High-performance printing platform

Standard APPE 3.0

APPE 3.0 (Adobe PDF Print Engine 3.0), which supports PDF transparency, is provided as a standard feature.

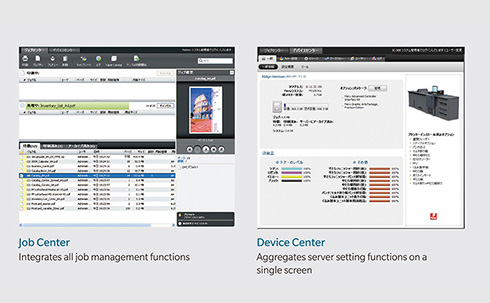

Print job management interface

Command Work Station

This software allows efficient job management on a PC via Job Center and Device Center screens.

Affinity with Creo RIP

High-performance Creo Controller

The external Creo® Print Controller IC-314 option features everything from advanced colour profiling and destination profiles to spot colours, a complete Pantone GOE library, colour sets, colour print sets, an Easy VIPP file creator, advanced perfect binder support and full integration with Kodak print systems.

Office machine connection

Open API/IWS compatible

bizhub Connector allows apps to be registered for easy access to cloud services*1 or a Microsoft SharePoint Server*2 from this machine’s control panel for direct printing and uploading of scanned data. OpenAPI 4.7 is also installed to allow the use of apps for authorisation, billing, ubiquitous printing, etc.

*1:Google Drive, Gmail, Evernote.

*2:SharePoint Server 2007/2010/2013/2016.

Maximum environmental consideration

Energy savings

Energy use is minimised by highly efficient Simitri HDE toner and an optimised transfer process that enables low fusing temperatures. Resources such as paper and toner are also efficiently used.

Eco materials

The C6100 series is constructed using a higher percentage of recycled resins, bioplastics and other eco materials. A lead-free shaft is also adopted to protect the environment and user.

| Model Name | AccurioPress C6100 |

| Type | Console type |

| Colour Support | Full colour |

| Writing Resolution | 3,600 (Equivalent) × 1,200 dpi |

| Gradation | 8-bit / 256 gradation |

| CPU | Intel Core i5 4570S 2.9 GHz |

| Memory Capacity |

Image memory: 5GB, System memory: 8GB (System memory capacity is expanded to 12GB with UK-110 mounted and 20GB with IC-604 mounted) *Additional 4GB in the with IQ-501+VI-511 installed |

| Warm-up Time | 480 seconds or less |

| Paper Size | Min. 100 mm × 139.7 mm, Max. 330.2 mm × 487.7 mm (with banner kit: max. 1,300 mm long) |

| Image Loss |

Max. 4.0 mm or less for top edge, Max. 4.0 mm or less for bottom edge, Max. 3.0 mm or less for right / left edges (6mm at the bottom edge with thick paper of 200 gsm or more) |

| Max. Printing Area | 321 mm x 480 mm (Banner paper: 321 mm x 1,295 mm) |

| Paper Weight | 52gsm to 400gsm |

| Continuous Print Speed Full Colour/ Black & White |

100 pages/min. (A4 landscape) 53 pages/min. (A3) |

| Power Source |

Inch : AC208 to 240V 24A 60Hz Metric : AC220 to 240V 25A, 50Hz / 60Hz |

| Power Consumption |

Inch: 5,760W or less (Main body only) Metric: 6,000W or less (Main body only) |

| Dimensions ( W × D × H ) |

950×950×1,319mm (Main unit only, control panel, dust vacuum box, working table, rear duct not included) |

| Space Requirements | Rear: 500mm or more, sides: 100mm or more work space required |

| Weight | Approx. 440 kg |

| Model Name | AccurioPress C6085 |

| Type | Console type |

| Colour Support | Full colour |

| Writing Resolution | 3,600 (Equivalent) × 1,200 dpi |

| Gradation | 8-bit / 256 gradation |

| CPU | Intel Core i5 4570S 2.9 GHz |

| Memory Capacity |

Image memory: 5GB, System memory: 8GB (System memory capacity is expanded to 12GB with UK-110 mounted and 20GB with IC-604 mounted) *Additional 4GB in the with IQ-501+VI-511 installed |

| Warm-up Time | 480 seconds or less |

| Paper Size | Min. 100 mm × 139.7 mm, Max. 330.2 mm × 487.7 mm (with banner kit: max. 1,300 mm long) |

| Image Loss |

Max. 4.0 mm or less for top edge, Max. 4.0 mm or less for bottom edge, Max. 3.0 mm or less for right / left edges (6mm at the bottom edge with thick paper of 200 gsm or more) |

| Max. Printing Area | 321 mm x 480 mm (Banner paper: 321 mm x 1,295 mm) |

| Paper Weight | 52gsm to 400gsm |

| Continuous Print Speed Full Colour/ Black & White |

85 pages/min. (A4 landscape) 46 pages/min. (A3) |

| Power Source |

Inch : AC208 to 240V 24A 60Hz Metric : AC220 to 240V 25A, 50Hz / 60Hz |

| Power Consumption |

Inch: 5,760W or less (Main body only) Metric: 6,000W or less (Main body only) |

| Dimensions ( W × D × H ) |

950×950×1,319mm (Main unit only, control panel, dust vacuum box, working table, rear duct not included) |

| Space Requirements | Rear: 500mm or more, sides: 100mm or more work space required |

| Weight | Approx. 440 kg |

| Type | Server |

| CPU | Intel Core i7-4790S 3.2GHz |

| Memory | 12 GB (7 GB: system memory, 5 GB: image memory) |

| HDD | 3 × 1 TB (1 TB system disk, 2 × 1 TB image disks) |

| Page-description Language | Adobe PostScript 3 (PS3020), PDF v1.7, APPE v3.4, PDF/X-1a/3/4, PDF/VT-2, TIFF v6.0, TIFF/IT, PPML v2.2, VPS, PPML/VDX, XPS |

| Printing Method | TCP/IP, SMB, LPR/LPD, IPP, Bonjour |

| Applicable OS |

Windows 7*1 / 8.1*1 / 10*1 Windows Server 2008*1 / 2008R2*1 / 2012*1 Mac OS X v10.8 / v10.9 / v10.10 / v10.11 |

| Interface | Ethernet (1000BASE-T / 100BASE-TX / 10BASE-T) with IPv6, USB 2.0 / 3.0 |

| Scanner Resolution*2 | 200 / 300 / 400 / 600 dpi |

| Scan Data Format*2 | PDF, TIFF, JPEG |

*1 Including 64-bit versions.

*2 Only when PF-711 is equipped.

| Type | Server |

| CPU | Xeon E5-2637 3.5GHz |

| Memory | 16 GB |

| HDD | 500 GB + 2 × 2 TB |

| Page-description Language | Adobe PostScript 3 (PS3020), PDF v1.7, APPE 3.0, PDF/VT-2, PPML v3.0, PCL 5/6 emuration |

| Printing Method | TCP/IP, SNMP, SMB, FTP, IPP, Bonjour |

| Applicable OS |

Windows 7*1 / 8.1*1 / 10*1 Windows Server 2008*1 / 2008R2*1 / 2012*1 Mac OS X v10.8 / v10.9 / v10.10 / v10.11 |

| Interface | Ethernet (1000BASE-T / 100BASE-TX / 10BASE-T) with IPv6, USB 2.0 / 3.0 |

| Scanner Driver*2 | Twain Plug-in |

| Scanner Resolution*2 | 200 / 300 / 400 / 600 dpi |

| Scan Data Format*2 | PDF, TIFF, JPEG |

*1 Including 64-bit versions.

*2 Only when PF-711 is equipped.

| Type | AIO to the engine (option) | |

| CPU | Conforms with main unit specification | |

| Memory | 20 GB (Details: 8 GB (Standard of the main body) + 12 GB (IC-604)) | |

| HDD | 4 TB (Details: 1 TB × 4) | |

| Page-description Language | Adobe PostScript3 (PS3020), PDF v1.7, APPE v4.2, PDF/VT-2, TIFF v6, PPML v2.2, PCL-5c, PCL6 v3 |

|

| Printing Method | TCP/IP(LPR/LPD, Raw Port, socket), IPX/SPX(NDS, Bindery), NetBEUI, IPP, Apple Talk, WSD, Bonjour, SMB |

|

| Applicable OS | PS Plug-in: |

Windows 7 / 8.1 / 10 Windows Server 2008 / 2008R2 / 2012*1 / 2016*1 Mac OS X 10.8 / 10.9 / 10.10 / 10.11 / 10.12 |

| PS PPD*2: | Windows 7 / 8.1 / 10 Windows Server 2008 / 2008R2 / 2012*1 / 2016*1 Linux CUPS | |

| Interface | Ethernet (1000BASE-T / 100BASE-TX / 10BASE-T) with IPv6, USB 2.0 | |

| Scanner Driver*3 | HDD Twain Driver, Real Time Mode Twain Driver | |

| Scanner Resolution*3 | 200 / 300 / 400 / 600 dpi | |

| Scan Data Format*3 | PDF, TIFF, JPEG, XPS | |

*1 Including 64-bit versions.

*2 WHQL is not obtained for the PS PPD driver.

*3 Only when PF-711 is equipped.