AccurioLabel 400

Important developments of the new AccurioLabel 400 press include the ability to expand applications with white toner, improved productivity with superfast print speeds of up to 39.9 metres per minute, and further running cost reductions thanks to even more durable parts life, as well as enhanced print quality. It is available in 4- and 5-colour configurations.

Key features

Enhanced Productivity

39.9 meter/minute

Enhanced Adaptability

White color allows expanded support for film application

Enhanced Image Quality

Uses IQ520 as standard for real time color stability control

Improved cost performance

Machine lifespan extended to 15000KM

The AccurioLabel 400 is the next solution from Konica Minolta’s successful journey in the digital label printing segment and will complement the AccurioLabel 230, one of the top-selling digital label presses in the world. Label converters and professional print providers with higher print volumes benefit from higher print speeds, white toner, longer print runs and user-friendly automation tools.

The AccurioLabel 400 offers outstanding productivity, brilliant image quality and surprising ease of use. This is your answer to the challenge of shorter delivery times, personalisation and versioning as well as instant production of on-demand print runs – which makes it your perfect tool to use in conjunction with existing analogue equipment and to diversify into new markets.

Market Trends

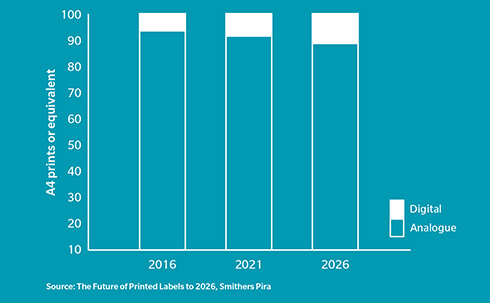

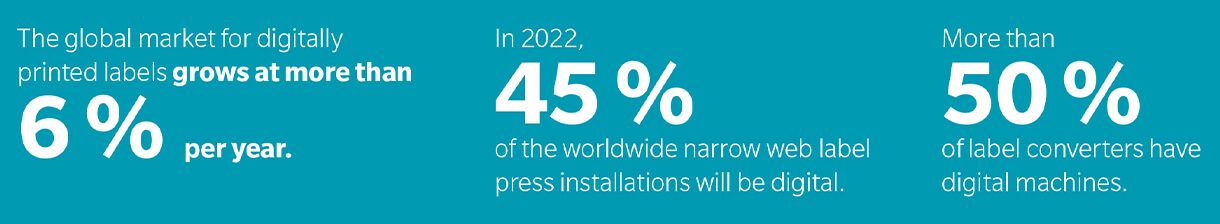

Growth Market: Digital continues to conquer the label printing market

The label printing market is considered one of the market segments that will continue to grow in the future. According to recent surveys, the majority of new, narrow-web label presses installed worldwide is digital.

The global printed label market was valued at $41.75 million in 2021 and is expected to grow at rates of around 6% per year.

Flux Label Impose rethink workflow

For reasons of efficiency and economy, label-manufacturing printers need to automate and integrate their workflow as much as possible. Equally important is the optimised use of media to avoid any waste of label material. This is why multiple labels are usually imposed across the width and length of the label web – a process that can easily become a complicated and time-consuming procedure if performed manually.

The Flux Label Impose software tool offers the perfect solution to this challenge: the application provides a simple and intuitive user interface for the automatic imposition and preparation of label jobs for printing.

Typical Applications Label Substrates

Glossy or matt adhesive paper, YUPO, PET, PP. An extended list of supported substrates from the major vendors of self-adhesive media is provided upon purchase of the AccurioLabel 400.

Create personalised and unique labels.

For short to medium production of labels for local produce.

Create wonderful labels for wines and spirits simply by producing great quality on untreated textured papers.

Private label products, ...

Allows for easy production of different versions of the same label.

For GHS labels, chemical products, identification, ...

Enabling New Print Applications.

The newly added 5th colour station with white toner can be used for a broad range of applications. The high opacity white adds “ no-label look” layouts to the range of print products possible with AccurioLabel 400.

See The Potential.

The “no-label look” can be creatively combined with subtle designs, using the combination of process colours and selected use of high opacity white.

Rethink What Labels Can Do For Your Business.

With white toner, you can now create stunning label designs with colourful and shimmering effects on metallic substrates – like here for coffee beans.

The label printing business is vibrant, dynamic and incredibly exciting.

The use of white toner opens up amazing new possibilities for creative label design – as shown here for wine bottles.

Realise the potential.

The demand for more sustainable label production is increasing – rightly enough. With the capability of printing on plant based substrates, the organic food and cosmetic sectors can be supplied with prints from AccurioLabel 400.

Ignite Your Print Possibilities.

Same goes for the huge sector of wine labels: With sustainable label substrates – such as grass paper – AccurioLabel 400 makes your label designs stick out with high quality combinations of CMYK elements, white toner and embellishment with varnish and foil effects. Digital label printing has been on the rise during recent years, and we see print volumes growing even more in the future.

10 Good Reasons

Good Reasons to change from an analogue workflow to digital label printing with the AccurioLabel 400.

Konica Minolta‘s AccurioLabel 400 lets you print variable images and text, fully integrated into your digital workflow. Imagine the many ways in which personalised label printing can help your business.

Short runs of different labels are easy and quick to produce, with no additional prep-time and make-ready. Short-run printing can be more effective and profitable.

With no prepress setup time, personalised labels can start printing without delay

Think about it: Less waste, zero plates used, minimal labour requirements – it all adds up to lower running costs and increased profitability

The AccurioLabel 400 is a compact digital label press with just 12‘ separating the unwinder and the rewinder, so that it will fit into the tightest of spaces on your production floor.

Complete colour management control ensures consistency across the substrate from the beginning to the end of your entire press run.

Digital control is far simpler than that of conventional analogue systems – and you can queue jobs right from your touch screen control panel, making reprints faster and more cost-effective.

The AccurioLabel 400 perfectly complements your analogue and digital production flow, allowing you to shift even higher print volumes to your digital output stream.

Larger roll capacity, longer print runs, ease-of-use and e ective automation tools make your label printing a no-brainer.

| Technology |

DryToner Electrophotography |

|

| Colour | CMYK, white (optional) |

|

| Resolution |

Main scan: 1,200 dpi (3,600 dpi equivalent) Sub scan: 2,400 dpi (8 bit) |

|

| Tone scale | 256 steps (8 bit), 16,700,000 colours |

|

| Printing speed |

39.9 m/min. (CMYK), down to 20 m/min. (CMYK+W), 39.9, 34.2, 30, 20, 15 m/min. depending on media types |

|

| Substrate thickness | Maximum roll diameter capacity: 850 mm; Standard inside core diameter: 3 inches; Maximum roll weight: ±120 kg. |

|

| Web control |

Integrated web guide system (BST) on infeed section and rewinder |

|

| Shaft diameter |

3 inches |

|

| Paper widths | 165 to 330 mm |

|

| Max. printed image width (length) | 320 mm |

|

| Media thickness (weight) | 60 to 250 µm |

|

| Supported substrates | Paper, PP, PET |

|

| Machine dimensions (L x W x H) | 7,160 x 1,435 x 1,628 mm 7,360 x 1,538 x 1,905 mm (Pro version) |

|

| Machine Floor Layout (L x W x H) | 7,930 x 2,130 x 1,628 mm 8,130 x 2,145 x 1,905 mm (Pro version) |

|

| Machine weight | 2,920 kg 3,520 kg (Pro version) |

|

| Max. roll diameter | 1,000 mm (unwinder and rewinder |

|

| Options |

- Corona treater - Unwind unit for lamination - Drawer dusty cleaner -double sides |

|

| Konica Minolta Controller |

IC-611 |

|

| Kodak (Creo) Controller, optional | IC-320L |

|

| Print engine |

2 x Single Phase 220-230 V, 25A, 50/60Hz |

|

| RE-101 | 1 x Single Phase 15A, 50/60Hz |

|

| IQ-520 |

1x 200-240 V, 3 A, Single Phase 50-60 Hz |

|

| Winders | 1 x 3 Phase 380V,26A,50/60Hz 1 x 3 Phase 380V,39A,50/60Hz (Pro version) |

|

| Formats |

Compressed air |

|

| Environment requirement | Temperature: 18-23 °C Humidity: 40% to 60% RH |

|